Camlock couplings vs Storz couplings

Camlock couplings and Storz couplings are among the most popular quick couplings on the market. However, the main difference between them is in their construction. Camlock couplings contain a plug and a socket and Storz couplings have two symmetrical parts.

Therefore, in this article, we have a look at both solutions. We review what the Camlock and Storz couplings are, and analyse and compare their strengths and weaknesses.

What are Camlock couplings?

Camlock couplings are one of the most popular industrial couplings. They were developed in the early 20th century and are distinguished by their simple design, which will find them easy to use.

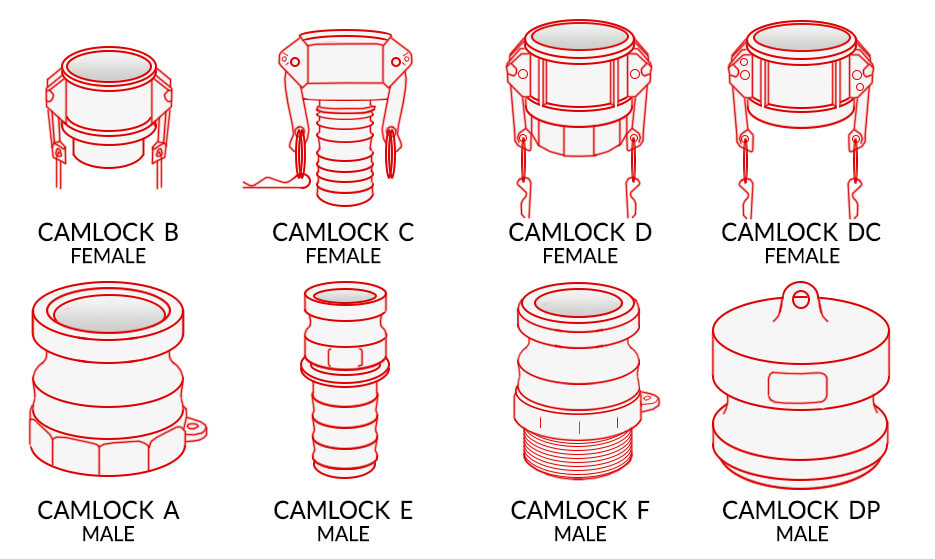

To achieve a tight seal, you insert the male element (the plug) into the female element (the socket) with the lugs, and then tighten the latter. Additional security is achieved when you lock the lugs with a safety pin.

Camlock couplings come in many versions and varieties, so you can easily choose the right product for your needs.

What are Storz couplings?

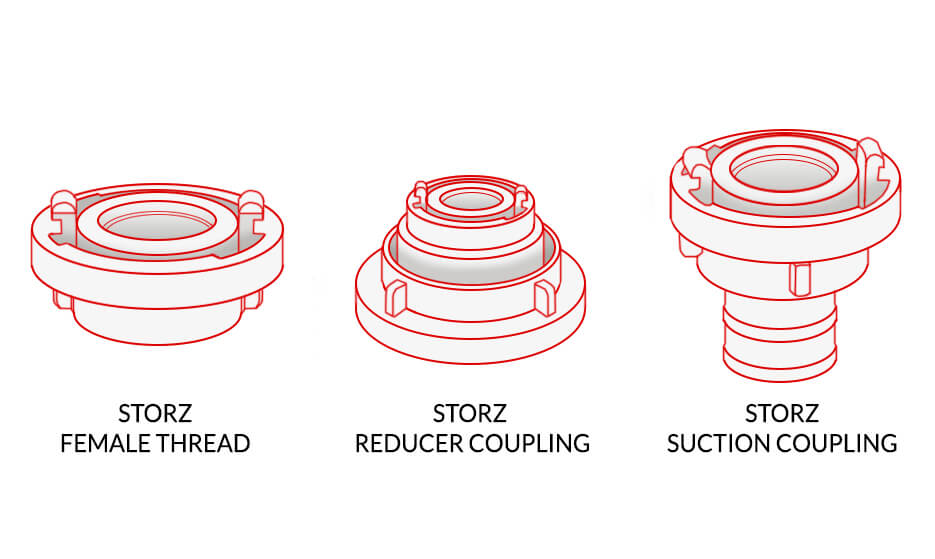

Storz couplings are symmetrical couplings that have become widespread in many European countries as the standard when it comes to firefighting hoses and fittings. They were developed in 1882 by Guido Storz. They also owe their name to him.

Although you will most often encounter Storz couplings in the fire service, they also have many industrial applications. They are suitable, among other things, for transporting chemicals, food, water and other liquids

They are also distinguished by their simple construction, as the connection is formed by two identical parts. Each has two lugs on the swivel cap. The connection is achieved when you put the two parts together and make a 1/4 turn.

What are the differences between Camlock couplings and Storz couplings?

The main difference between Camlock couplings and Storz couplings is the different construction. Camlock couplings consist of a plug and a socket, whereas the Storz couplings have two symmetrical parts. As a result, the connection method is also different, but both are characterised by simplicity and speed of use.

Furthermore, Camlock couplings have more components in their construction. Some of them (e.g. the handles) are movable and wear out more quickly. Therefore, they need to be replaced from time to time.

In addition to this, the Camlock system offers slightly more choice in terms of material versions, types, sizes, as well as additional accessories.

Differences include the fact that Storz couplings sometimes lock under pressure. If this happens, you will need a special spanner to unscrew them.

What are the advantages of Camlock couplings?

The advantages of Camlock couplings are as follows:

- simplicity and speed of use,

- strength,

- durability,

- affordable price,

- high resistance to leakage,

- easy to maintain,

- wide range of sizes and material versions.

What are the disadvantages of Camlock couplings?

The disadvantages of Camlock couplings are as follows:

- for safety reasons, they are not suitable for transporting compressed air, steam and other pressurised gases;

- have several moving parts that wear out more quickly and thus need to be replaced regularly.

What are the advantages of Storz couplings?

The advantages of Storz couplings are as follows:

- easy and quick assembly/disassembly,

- symmetrical (both parts of the coupling are the same, there is no division into plug and socket),

- strength,

- durability,

- resistance to contamination,

- large passage,

- several material versions to choose from.

What are the disadvantages of Storz couplings?

The disadvantages of Storz couplings are as follows:

- for safety reasons, they are not suitable for transporting compressed air, steam and other pressurised gases;

- in the moulded version, the couplings have a much lower strength and there is a risk of structural defects (which is why the forged version is much more popular);

- tend to lock under pressure, so that disconnection may require a special Storz spanner.

When to use Camlock couplings?

You can use Camlock couplings in most cases where bulk or liquid media transport is involved. They are most often used in the chemical and petrochemical industries, but will also prove useful in the food, pharmaceutical, agricultural and construction sectors, as well as in the military and defence industries.

They make work much easier wherever there is a need to frequently connect and disconnect hoses and pipes.

When to use Storz couplings?

You can use Storz couplings whenever you transfer bulk and liquid media. Although most associate them as firefighting couplings, in addition to firefighting and fire protection, they are also used in the chemical and food industries, agriculture, as well as septic tankers and transport with tankers.

As Storz couplings are symmetrical, they will work in any situation where a quick and easy way of connecting/disconnecting is required. As long as the products are the same size, there is no risk of mix-ups, and you won't have to turn the hose over, for example (which takes valuable time in firefighting).

Summary

Although with both Camlock and Storz couplings you are dealing with quick release couplings, there is a clear difference between the two. It can be seen primarily in the construction, because in the first case the system consists of a male and a female component, while in the second case there is no such division - both Storz parts are identical.

Besides, the Camlock has several moving elements that are wearing out.

On the other hand, you will buy Storz in two versions: moulded and forged. The former is not made to standards and is less robust than the latter.

Either way, both systems have similar applications, so ultimately it is only up to you to decide which one you will use in your installation. Now you know what the differences are, you will find it easier to make the right choice.

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

What are Camlock couplings?

What are Storz couplings?

What are the differences between Camlock couplings and Storz couplings?

What are the advantages of Camlock couplings?

What are the disadvantages of Camlock couplings?

What are the advantages of Storz couplings?

What are the disadvantages of Storz couplings?

When to use Camlock couplings?

When to use Storz couplings?

Summary

See also other categories