Trapezoidal thread - asymmetric and symmetric - dimensions, chart

What is a trapezoidal thread?

The trapezoidal thread is a type of thread in which the crests and roots take the form of a trapezoid. This is the main difference from traditional thread types, which are triangular.

What are the types of trapezoidal threads?

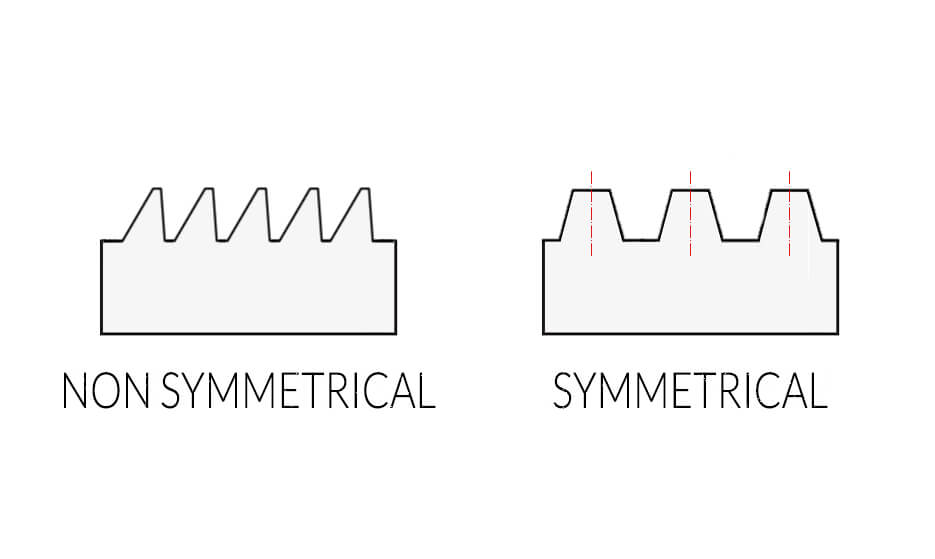

There are two types of trapezoidal threads:

- symmetric trapezoidal threads (also referred to as “metric”),

- asymmetric trapezoidal threads.

They differ from each other in shape and application, as you will read more about below.

What is a symmetric trapezoidal thread?

Symmetric trapezoidal thread is a thread that is characterised by crests and roots in the shape of an isosceles trapezoid. As its strength is high, it is used primarily in two cases:

- in highly loaded mechanisms that operate less frequently and at low speeds (e.g. screw jack screws and valve spindles),

- in screws that carry a heavy load in both directions (e.g. lead screws of the lathes).

What is an asymmetric trapezoidal thread?

Asymmetric trapezoidal thread is a thread that is characterised by its crests and roots take the shape of a right trapezoid. This gives it enormous strength, but it can only be loaded in one direction.

This is why you will most often find them in fly presses or clamping devices for rollers, hooks or cranes.

In general, the symmetric trapezoidal thread is more versatile, as it retains its properties in both directions of operation.

What are the applications of the trapezoidal thread?

Trapezoidal thread is only used in practice in so-called movement connections.

The driving force of such a system is the nut (female trapezoidal thread), for which the movement route is the screw (male trapezoidal thread). Usually, the design works in such a way that when the screw starts rotating, it sets the details of the device in motion.

The simplest example of a system of this type is a car jack.

Unfortunately, trapezoidal threads also have disadvantages. They are characterised by high friction and backlash, making them unlikely to prove themselves as a precision drive.

What are the designations of the trapezoidal thread?

The first and most important trapezoidal thread designation is the "Tr" or "S" symbol. It lets you know that you are dealing with a trapezoidal thread (“Tr” stands for symmetric and “S” for asymmetric thread).

Right behind it, you will find information on the nominal diameter of the thread (symbol "d" for a screw and "D" for a nut) and the pitch of the thread (P). Therefore, an example designation would look as follows:

Tr24x5

It tells you that you are dealing with a trapezoidal thread with a diameter of 24 mm and a pitch of 5.

If it was a left-hand thread, the designation has the additional information "LH" (left hand).

What are the dimensions of the trapezoidal thread? Trapezoidal threads chart

Trapezoidal thread is present in multiple different dimensions. You will find all the necessary information in the chart below:

| Designation | d [mm] | P [mm] | D1=d1 [mm] | D2=d2 [mm] | d3 [mm] | D4 [mm] | R1 [mm] | R2 [mm] |

|---|---|---|---|---|---|---|---|---|

| Tr 8×1,5 | 8 | 1.5 | 6.8 | 7.3 | 6.5 | 8.3 | 0.075 | 0.15 |

| Tr 9×1,5 | 9 | 1.5 | 7.8 | 8.3 | 7.5 | 9.3 | 0.075 | 0.15 |

| Tr 9×2 | 9 | 2 | 7.5 | 8 | 7 | 9.5 | 0.125 | 0.25 |

| Tr 10×1.5 | 10 | 1.5 | 8.8 | 9.3 | 8.5 | 10.3 | 0.075 | 0.15 |

| Tr 10×2 | 10 | 2 | 8.5 | 9 | 8 | 10.5 | 0.125 | 0.25 |

| Tr 11×2 | 11 | 2 | 9.5 | 10 | 9 | 11.5 | 0.125 | 0.25 |

| Tr 11×3 | 11 | 3 | 8.5 | 9.5 | 8 | 11.5 | 0.125 | 0.25 |

| Tr 12×2 | 12 | 2 | 10.5 | 11 | 10 | 12.5 | 0.125 | 0.25 |

| Tr 12×3 | 12 | 3 | 9.5 | 10.5 | 9 | 12.5 | 0.125 | 0.25 |

| Tr 14×2 | 14 | 2 | 12.5 | 13 | 12 | 14.5 | 0.125 | 0.25 |

| Tr 14×3 | 14 | 3 | 11.5 | 12.5 | 11 | 14.5 | 0.125 | 0.25 |

| Tr 16×2 | 16 | 2 | 14.5 | 15 | 14 | 16.5 | 0.125 | 0.25 |

| Tr 16×4 | 16 | 4 | 12.5 | 14 | 12 | 16.5 | 0.125 | 0.25 |

| Tr 18×2 | 18 | 2 | 16.5 | 17 | 16 | 18.5 | 0.125 | 0.25 |

| Tr 18×4 | 18 | 4 | 14.5 | 16 | 14 | 18.5 | 0.125 | 0.25 |

| Tr 20×2 | 20 | 2 | 18.5 | 19 | 18 | 20.5 | 0.125 | 0.25 |

| Tr 20×4 | 20 | 4 | 16.5 | 18 | 16 | 20.5 | 0.125 | 0.25 |

| Tr 22×3 | 22 | 3 | 19.5 | 20.5 | 19 | 22.5 | 0.125 | 0.25 |

| Tr 22×5 | 22 | 5 | 17.5 | 19.5 | 17 | 22.5 | 0.125 | 0.25 |

| Tr 22×8 | 22 | 8 | 15 | 18 | 14 | 23 | 0.25 | 0.5 |

| Tr 24×3 | 24 | 3 | 21.5 | 22.5 | 21 | 24.5 | 0.125 | 0.25 |

| Tr 24×5 | 24 | 5 | 19.5 | 21.5 | 19 | 24.5 | 0.125 | 0.25 |

| Tr 24×8 | 24 | 8 | 17 | 20 | 16 | 25 | 0.25 | 0.5 |

| Tr 26×3 | 26 | 3 | 23.5 | 24.5 | 23 | 26.5 | 0.125 | 0.25 |

| Tr 26×5 | 26 | 5 | 21.5 | 23.5 | 21 | 26.5 | 0.125 | 0.25 |

| Tr 26×8 | 26 | 8 | 19 | 22 | 18 | 27 | 0.25 | 0.5 |

| Tr 28×3 | 28 | 3 | 25.5 | 26.5 | 25 | 28.5 | 0.125 | 0.25 |

| Tr 28×5 | 28 | 5 | 23.5 | 25.5 | 23 | 28.5 | 0.125 | 0.25 |

| Tr 28×8 | 28 | 8 | 21 | 24 | 20 | 29 | 0.25 | 0.5 |

| Tr 30×3 | 30 | 3 | 27.5 | 28.5 | 27 | 30.5 | 0.125 | 0.25 |

| Tr 30×6 | 30 | 6 | 25 | 27 | 24 | 31 | 0.25 | 0.5 |

| Tr 30×10 | 30 | 10 | 21 | 25 | 20 | 31 | 0.25 | 0.5 |

| Tr 32×3 | 32 | 3 | 29.5 | 30.5 | 29 | 32.5 | 0.125 | 0.25 |

| Tr 32×6 | 32 | 6 | 27 | 29 | 26 | 33 | 0.25 | 0.5 |

| Tr 32×10 | 32 | 10 | 23 | 27 | 22 | 33 | 0.25 | 0.5 |

| Tr 34×3 | 34 | 3 | 31.5 | 32.5 | 31 | 34.5 | 0.125 | 0.25 |

| Tr 34×6 | 34 | 6 | 29 | 31 | 28 | 35 | 0.25 | 0.5 |

| Tr 34×10 | 34 | 10 | 25 | 29 | 24 | 35 | 0.25 | 0.5 |

| Tr 36×3 | 36 | 3 | 33.5 | 34.5 | 33 | 36.5 | 0.125 | 0.25 |

| Tr 36×6 | 36 | 6 | 31 | 33 | 30 | 37 | 0.25 | 0.5 |

| Tr 36×10 | 36 | 10 | 27 | 31 | 26 | 37 | 0.25 | 0.5 |

| Tr 38×3 | 38 | 3 | 35.5 | 36.5 | 35 | 38.5 | 0.125 | 0.25 |

| Tr 38×7 | 38 | 7 | 32 | 34.5 | 31 | 39 | 0.25 | 0.5 |

| Tr 38×10 | 38 | 10 | 29 | 33 | 28 | 39 | 0.25 | 0.5 |

| Tr 40×3 | 40 | 3 | 37.5 | 38.5 | 37 | 40.5 | 0.125 | 0.25 |

| Tr 40×7 | 40 | 7 | 34 | 36.5 | 33 | 41 | 0.25 | 0.5 |

| Tr 40×10 | 40 | 10 | 31 | 35 | 30 | 41 | 0.25 | 0.5 |

| Tr 42×3 | 42 | 3 | 39.5 | 40.5 | 39 | 42.5 | 0.125 | 0.25 |

| Tr 42×7 | 42 | 7 | 36 | 38.5 | 35 | 43 | 0.25 | 0.5 |

| Tr 42×10 | 42 | 10 | 33 | 37 | 32 | 43 | 0.25 | 0.5 |

| Tr 44×3 | 44 | 3 | 41.5 | 42.5 | 41 | 44.5 | 0.125 | 0.25 |

| Tr 44×7 | 44 | 7 | 38 | 40.5 | 37 | 45 | 0.25 | 0.5 |

| Tr 44×10 | 44 | 10 | 35 | 39 | 34 | 45 | 0.25 | 0.5 |

Definition of symbols:

- P - thread pitch,

- D - nominal diameter of nut thread,

- d - nominal diameter of the screw thread,

- D1 - inner diameter of the nut thread,

- d1 - inner diameter of the screw thread,

- D2 - average diameter of the nut thread,

- d2 - average diameter of the screw thread,

- d3 - diameter of the screw core,

- R1 - radius of roundness of the tops of the coils of the screw and nut,

- R2 - the radius of roundness of the screw and nut coil gaps.

Tabela gwintów trapezowych niesymetrycznych

| Designation | d=D [mm] | P [mm] | d1 [mm] | D1 [mm] | d2=D2 [mm] | r [mm] | e [mm] |

|---|---|---|---|---|---|---|---|

| S 10×2 | 10 | 2 | 8,26 | 8,5 | 9,25 | 0,25 | 0,53 |

| S 12×2 | 12 | 2 | 10,26 | 10,5 | 11,25 | 0,25 | 0,53 |

| S 14×2 | 14 | 2 | 12,26 | 12,5 | 13,25 | 0,25 | 0,53 |

| S 16×2 | 16 | 2 | 14,26 | 14,5 | 15,25 | 0,25 | 0,53 |

| S 18×2 | 18 | 2 | 16,26 | 16,5 | 17,25 | 0,25 | 0,53 |

| S 20×2 | 20 | 2 | 18,26 | 18,5 | 19,25 | 0,25 | 0,53 |

| S 22×2 | 22 | 2 | 20,26 | 20,5 | 21,25 | 0,25 | 0,53 |

| S 22×5 | 22 | 5 | 17,66 | 18,25 | 20,13 | 0,62 | 1,32 |

| S 22×8 | 22 | 8 | 15,06 | 16 | 19 | 0,99 | 2,11 |

| S 24×2 | 24 | 2 | 22,26 | 22,5 | 23,25 | 0,25 | 0,53 |

| S 24×5 | 24 | 5 | 19,66 | 20,25 | 22,13 | 0,62 | 1,32 |

| S 24×8 | 24 | 8 | 17,06 | 18 | 21 | 0,99 | 2,11 |

| S 26×2 | 26 | 2 | 24,26 | 24,5 | 25,25 | 0,25 | 0,53 |

| S 26×5 | 26 | 5 | 21,66 | 22,25 | 24,13 | 0,62 | 1,32 |

| S 26×8 | 26 | 8 | 19,06 | 20 | 23 | 0,99 | 2,11 |

| S 28×2 | 28 | 2 | 26,26 | 26,5 | 27,25 | 0,25 | 0,53 |

| S 28×5 | 28 | 5 | 23,66 | 24,25 | 26,13 | 0,62 | 1,32 |

| S 28×8 | 28 | 8 | 21,06 | 22 | 25 | 0,99 | 2,11 |

| S 30×3 | 30 | 3 | 27,4 | 27,75 | 28,88 | 0,37 | 0,79 |

| S 30×6 | 30 | 6 | 24,79 | 25,5 | 27,75 | 0,75 | 1,58 |

| S 30×10 | 30 | 10 | 21,32 | 22,5 | 26,25 | 1,24 | 2,64 |

| S 32×3 | 32 | 3 | 29,4 | 29,75 | 30,88 | 0,37 | 0,79 |

| S 32×6 | 32 | 6 | 26,79 | 27,5 | 29,75 | 0,75 | 1,58 |

| S 32×10 | 32 | 10 | 23,32 | 24,5 | 28,25 | 1,24 | 2,64 |

| S 34×3 | 34 | 3 | 31,4 | 31,75 | 32,88 | 0,37 | 0,79 |

| S 34×6 | 34 | 6 | 28,79 | 29,5 | 31,75 | 0,75 | 1,58 |

| S 34×10 | 34 | 10 | 25,32 | 26,5 | 30,25 | 1,24 | 2,64 |

| S 36×3 | 36 | 3 | 33,4 | 33,75 | 34,88 | 0,37 | 0,79 |

| S 36×6 | 36 | 6 | 30,79 | 31,5 | 33,75 | 0,75 | 1,58 |

| S 36×10 | 36 | 10 | 27,32 | 28,5 | 32,25 | 1,24 | 2,64 |

| S 38×3 | 38 | 3 | 35,4 | 35,75 | 36,88 | 0,37 | 0,79 |

| S 38×6 | 38 | 6 | 32,79 | 33,5 | 35,75 | 0,75 | 1,58 |

| S 38×10 | 38 | 10 | 29,32 | 30,5 | 34,25 | 1,24 | 2,64 |

| S 40×3 | 40 | 3 | 37,4 | 37,75 | 38,88 | 0,37 | 0,79 |

| S 40×6 | 40 | 6 | 34,79 | 35,5 | 37,75 | 0,75 | 1,58 |

| S 40×10 | 40 | 10 | 31,32 | 32,5 | 36,25 | 1,24 | 2,64 |

| S 42×3 | 42 | 3 | 39,4 | 39,75 | 40,88 | 0,37 | 0,79 |

| S 42×6 | 42 | 6 | 36,79 | 37,5 | 39,75 | 0,75 | 1,58 |

| S 42×10 | 42 | 10 | 33,32 | 34,5 | 38,25 | 1,24 | 2,64 |

| S 44×3 | 44 | 3 | 41,4 | 41,75 | 42,88 | 0,37 | 0,79 |

| S 44×8 | 44 | 8 | 37,06 | 38 | 41 | 0,99 | 2,11 |

| S 44×12 | 44 | 12 | 33,59 | 35 | 39,5 | 1,49 | 3,17 |

| S 46×3 | 46 | 3 | 43,4 | 43,75 | 44,88 | 0,37 | 0,79 |

| S 46×8 | 46 | 8 | 39,06 | 40 | 43 | 0,99 | 2,11 |

| S 46×12 | 46 | 12 | 35,59 | 37 | 41,5 | 1,49 | 3,17 |

| S 48×3 | 48 | 3 | 45,4 | 45,75 | 46,88 | 0,37 | 0,79 |

| S 48×8 | 48 | 8 | 41,06 | 42 | 45 | 0,99 | 2,11 |

| S 48×12 | 48 | 12 | 37,59 | 39 | 43,5 | 1,49 | 3,17 |

| S 50×3 | 50 | 3 | 47,4 | 47,75 | 48,88 | 0,37 | 0,79 |

| S 50×8 | 50 | 8 | 43,06 | 44 | 47 | 0,99 | 2,11 |

| S 50×12 | 50 | 12 | 39,59 | 41 | 45,5 | 1,49 | 3,17 |

| S 52×3 | 52 | 3 | 49,4 | 49,75 | 50,88 | 0,37 | 0,79 |

| S 52×8 | 52 | 8 | 45,06 | 46 | 49 | 0,99 | 2,11 |

| S 52×12 | 52 | 12 | 41,59 | 43 | 47,5 | 1,49 | 3,17 |

| S 55×3 | 55 | 3 | 52,4 | 52,75 | 53,88 | 0,37 | 0,79 |

| S 55×8 | 55 | 8 | 48,06 | 49 | 52 | 0,99 | 2,11 |

| S 55×12 | 55 | 12 | 44,59 | 46 | 50,5 | 1,49 | 3,17 |

Definition of symbols:

- P - thread pitch,

- D - nominal diameter of nut thread,

- d - nominal diameter of the screw thread,

- D1 - inner diameter of the nut thread,

- d1 - inner diameter of the screw thread,

- D2 - average diameter of the nut thread,

- r - radius of the rounding of the thread base,

- e - height of the thread profile,

How to measure a trapezoidal thread?

You can easily measure trapezoidal threads using a calliper. The outer diameter can be checked with the jaws of the tool when you cover the widest part of the thread. By contrast, you can measure the inner diameter with the smaller jaws of the calliper, which must be inserted into the centre of the thread.

How to make a trapezoidal thread?

Special screw taps or milling cutters are most commonly used to produce the trapezoidal female thread. Whereas the male thread is produced with a lathe or a milling machine (sometimes also with a die nut).

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

What is a trapezoidal thread?

What are the types of trapezoidal threads?

What is a symmetric trapezoidal thread?

What is an asymmetric trapezoidal thread?

What are the applications of the trapezoidal thread?

What are the designations of the trapezoidal thread?

What are the dimensions of the trapezoidal thread? Trapezoidal threads chart

Tabela gwintów trapezowych niesymetrycznych

How to measure a trapezoidal thread?

How to make a trapezoidal thread?

See also other categories