45 Thread types – Thread identification

Threads may seem like small and inconspicuous parts, but they play a key role in countless applications - from holding things together to transforming rotary motion into linear motion. What's more, these spiral simple machines come in different types, each with its strengths and purpose.

Whether you are a DIY enthusiast or an engineer, understanding the different types of threads can unlock a whole new world of possibilities for you.

Therefore, in this article, we will look more deeply into the topic of threads. We will study their types, characteristics and applications.

What is a thread?

A thread is a spiral structure used to convert rotary motion into linear motion or force. It takes the form of a ridge wrapped in spiral form around a cylinder or cone - the former being called a cylindrical (straight) thread and the latter a conical thread.

The thread is the essential feature of the screw as a straight machine and a threaded fastener.

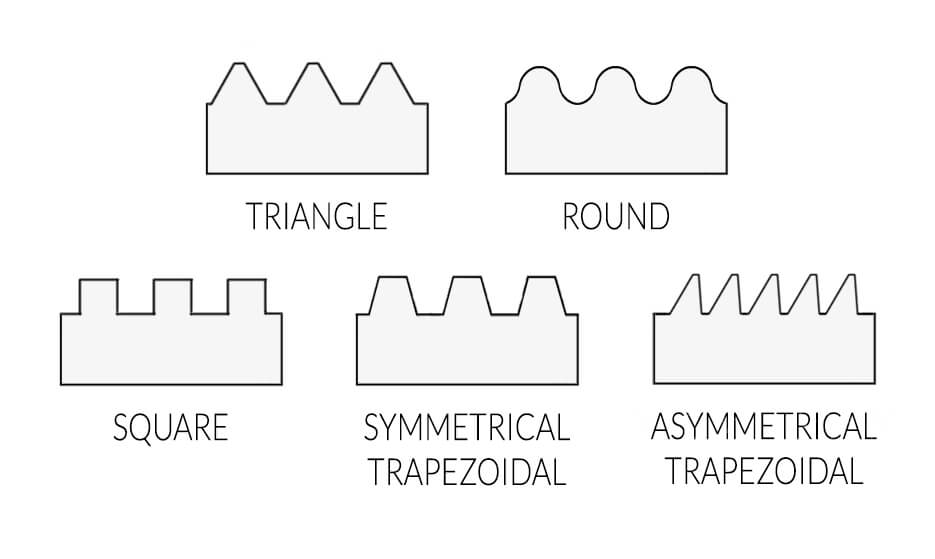

Shape-based thread classification

One of the basic distinctions we can make on threads is the classification by shape. In this respect you have:

- Symmetrical trapezoidal thread,

- Unsymmetrical trapezoidal thread,

- Round thread,

- Rectangular thread,

- Triangular thread.

Symmetrical trapezoidal thread

A symmetrical trapezoidal thread is a thread with a trapezoidal shape, both sides of which are symmetrical. Symmetrical trapezoidal thread is used in bidirectional mechanisms carrying heavy loads, as well as in devices that have a low rotational speed or operate infrequently.

Unsymmetrical trapezoidal thread

An asymmetrical trapezoidal thread is a thread with the outline of a trapezoid, one side being straight and the other oblique. It is characterised by its high strength, but can only be loaded in one direction.

Round thread

A round thread is a thread with a rounded (circular) outline. Because of this, it has high fatigue and static strength.

It is used in connections which are often disconnected and which face the risk of contamination or corrosion. Popular applications include, for example, the coupling of wagons or crane hooks.

Round threads are specified in the PN-84/M02035 standard.

Rectangular thread

The rectangular thread is a rectangular-shaped thread and is considered to be the oldest of all those mentioned. It is characterised by very high performance, but is also the least robust.

This type of thread has never been standardised.

Triangular thread

A triangular thread is a thread with a triangular outline, but very often has a rounded tip. This is due to the fact that the sharp ends are easily damaged, although they also find use (e.g. in screws for wood or plastic).

Triangular threads are commonly used in a variety of applications where secure fastening and self-tapping capabilities are required.

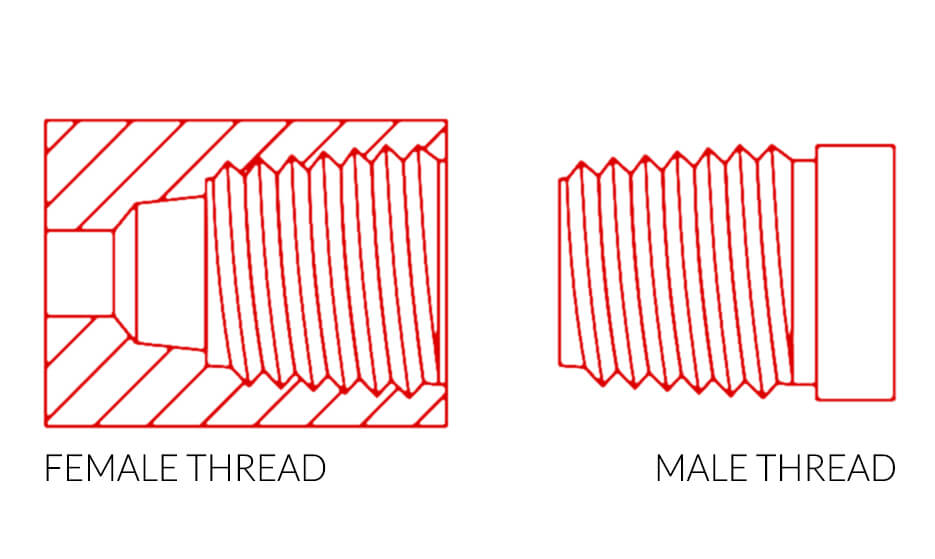

Classification of threads according to their placement

We divide threads by placement into external and internal threads.

External thread

An external thread is a thread on the outside of a cone or cylinder. It is usually found on bolts, studs or screws to provide a means of fastening and securing components together.

External threads are designed to connect to internal threads, allowing parts to be assembled and disassembled.

Internal thread

An internal thread is a thread that is cut or formed on the inner surface of a hollow cylinder or nut. Internal thread is used to connect to external threads so that various parts can be assembled and disassembled.

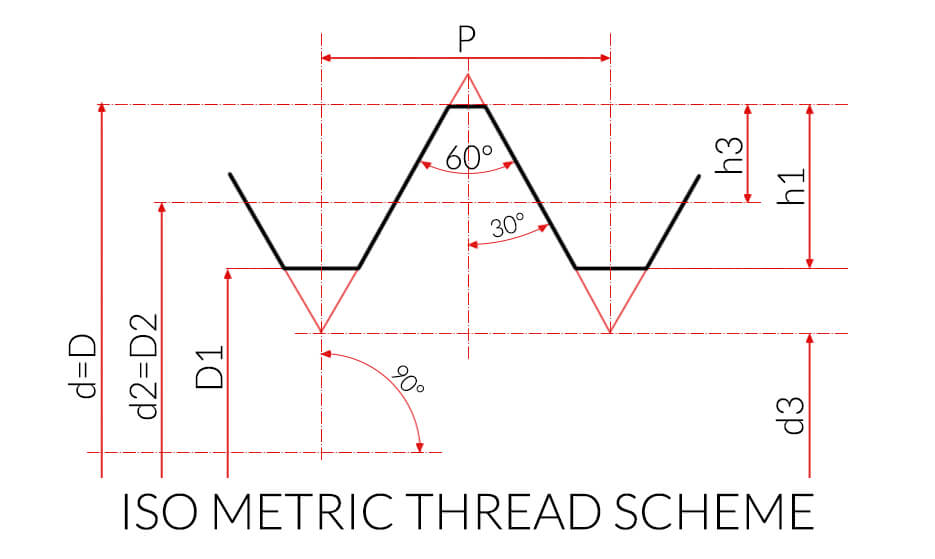

Classification of threads according to the measurement system

If we take into account the system of measurements, you will find two versions of threads on the market:

- Metric threads,

- Inch threads.

Metric thread

A metric thread is a thread that is defined by the distance between each vertex, known as pitch, which is measured in millimetres (mm). Its diameter is also given in millimetres.

The International Organisation for Standardisation (ISO) has established standards for metric threads. These specify design rules, dimensions and tolerances.

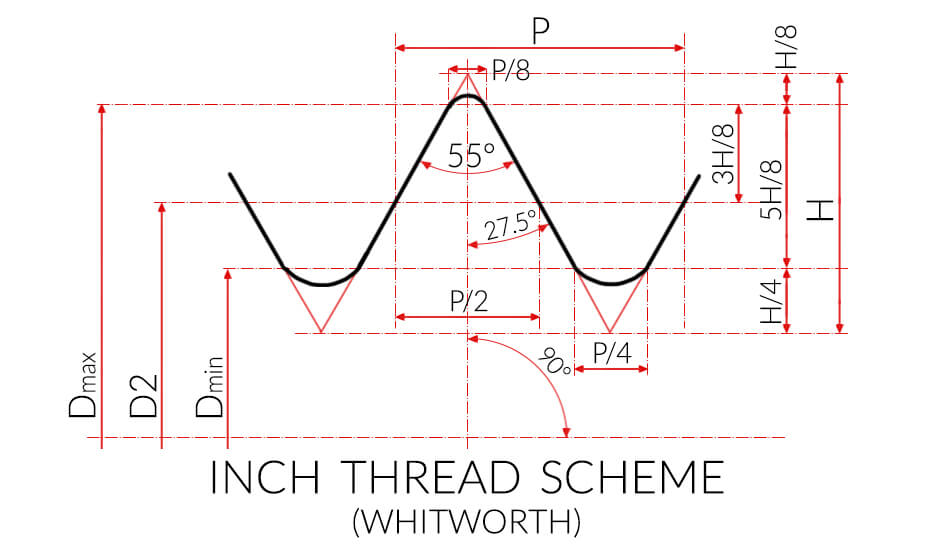

Inch thread

An inch thread is a thread that is defined by the number of vertices that fit into a section equal to 1 inch, usually measured in TPI (thread per inch).

Unlike metric threads, which are measured in millimetres, inch threads use the imperial system of measurement. They also have different standards.

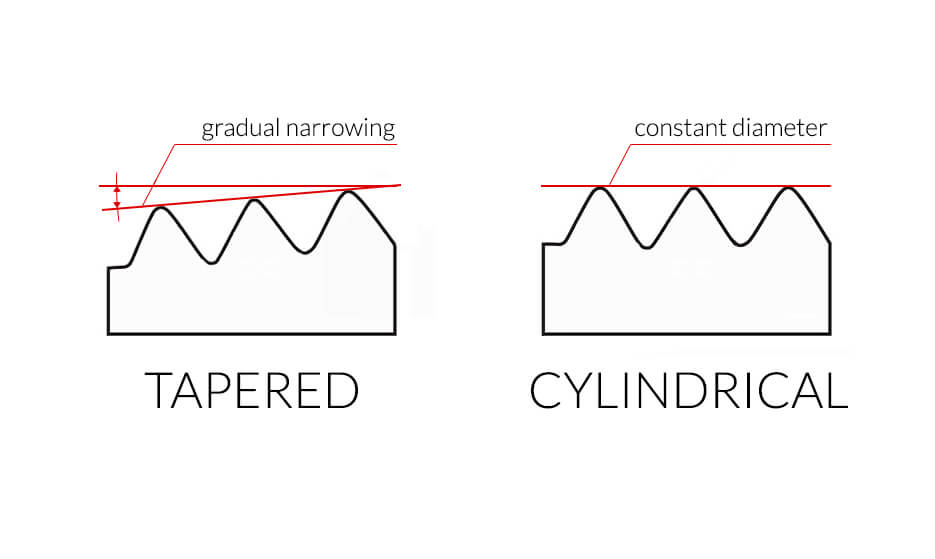

Classification of threads according to inclination

In terms of inclination, there are two types of threads:

- Tapered threads,

- Cylindrical threads.

Tapered thread

A tapered thread is a type of thread that tapers along the profile. In other words, its diameter decreases as it moves downwards.

Tapered threads are used to connect water pipes, fuel pipes, lubricant pipes, etc. They ensure a tight connection without the use of additional seals.

Cylindrical thread

A cylindrical thread is a type of thread that has a constant diameter along the entire length of the profile. Some also refer to it as a straight thread.

It is primarily used where secure, mechanical connections are required.

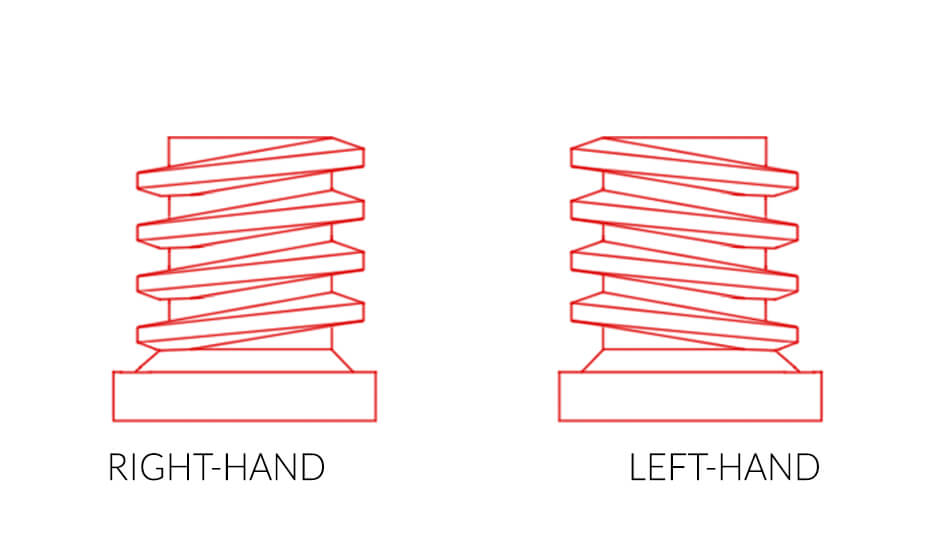

Classification of threads according to rotation direction

Threads are also classified according to the rotation direction into :

- Left-hand threads,

- Right-hand threads.

Right-hand thread

A right-hand thread is a type of thread which is screwed in clockwise. It is the most common type of thread and is used in most applications.

Left-hand thread

A left-hand thread is a type of thread that is screwed in counterclockwise. Although rarely used, it is used wherever it provides more advantages compared to a right-hand thread.

For example, you will find left-hand threads in rotating machinery, such as engine and turbine parts. This is because rotation can cause right-hand threads to loosen over time. Use of left-hand threads eliminates this risk.

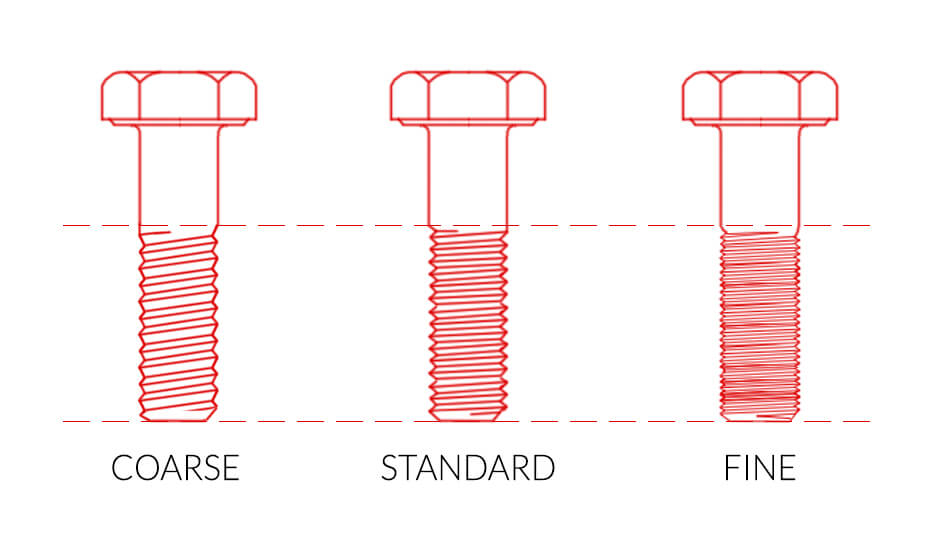

Classification of threads according to pitch

Last but not least, the pitch of threads, i.e. the distance between the vertices, is taken into account. In this respect, we distinguish between:

- Fine thread,

- Coarse thread,

- Normal thread.

Fine thread

A fine thread is a thread in which the distance between the vertices is smaller than standard. Fine thread has many advantages that make it the perfect choice when it comes to specificity. Precision threading has a higher tensile strength and can be measured accurately. This makes it a perfect choice for applications with a specific strength.

Fine threads also have a very shallow pitch. This makes vibration less effective in loosening fasteners.

Coarse thread

A coarse thread is a thread in which the distance between the vertices is larger than standard. Coarse thread is an ideal choice for most applications. It is common on construction sites because light damage does not affect its effectiveness.

As it allows more material to be placed between threads during assembly, fasteners are harder to strip or cross. In addition, the extra tolerance allows scratches or scrapes to occur on the edges of the threads without compromising their capabilities.

Normal thread

Normal thread is a type of thread with a standard pitch for a given diameter and thread type. It is neither fine threaded nor coarse threaded, but falls somewhere in between.

Popular thread standards

Threads have many standards. We have described the most popular ones below:

- NPT thread,

- BSP thread,

- Whitworth thread,

- Pipe thread,

- JIC thread,

- JIS thread,

- UNF thread,

- UNC thread,

- UNEF thread,

- UN thread,

- UNS thread,

- ACME thread,

- G-thread (BSPP),

- R-thread (BSPT),

- NPTF thread,

- SAE thread,

- ORFS thread,

- BSW thread,

- Edison thread,

- Pg thread,

- Tr thread,

- Rp thread,

- Rc thread,

- NC thread,

- RD thread,

- S-thread,

- Ven thread, VG thread,

- W thread.

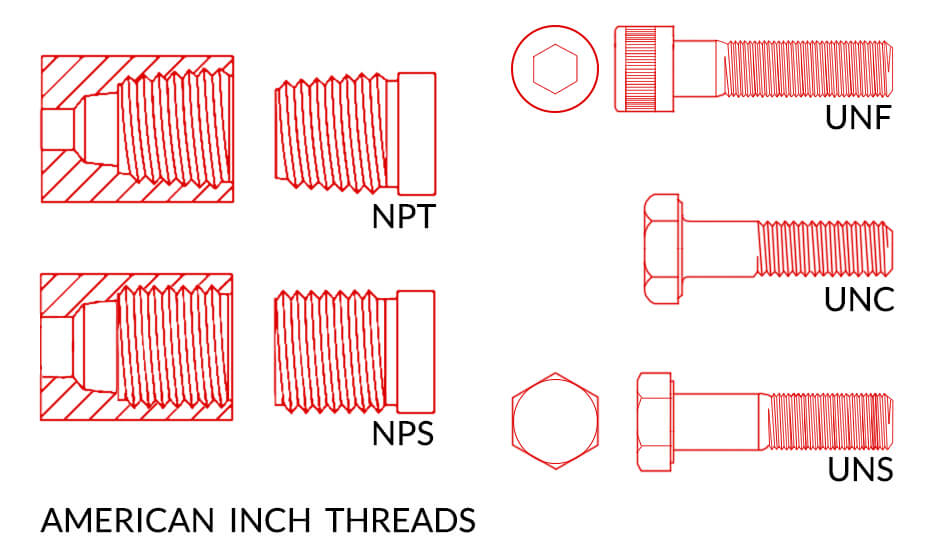

NPT thread,

The NPT thread is the American standard thread used to connect hoses and fittings in the hydraulic industry. NPT stands for "National Pipe Thread." NPT threads can be cylindrical or tapered and have a 60° angle with flat vertices and roots.

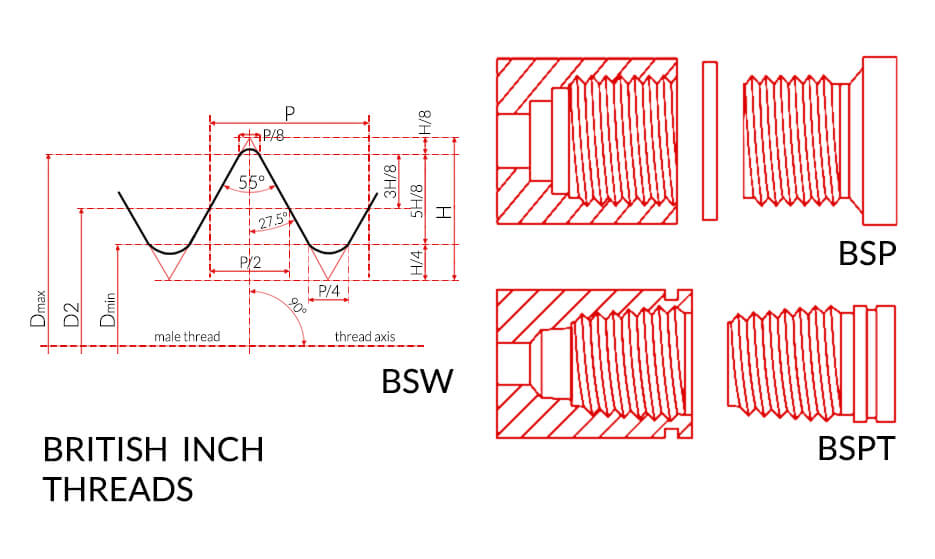

BSP thread

BSP thread is a set of technical standards for screw threads, internationally accepted for connecting and sealing pipes and fittings. BSP stands for "British Standard Pipe". BSP threads are based on the Whitworth thread form. They can be cylindrical or tapered and have a thread angle of 55°

Whitworth thread

The Whitworth thread is a type of thread developed by Sir Joseph Whitworth in 1841 in England. It was the world's first standardised type of thread.

Indeed, the shape of the Whitworth thread is based on a basic triangle with an angle of 55° at each vertex and root, and the sides are perpendicular to the axis at Θ = 27.5°. Whitworth threads can be cylindrical or tapered and are commonly used in pipe assemblies throughout Europe.

Pipe thread

A pipe thread is a type of thread used to connect and seal pipes and fittings. Pipe threads can be cylindrical or tapered and are commonly used in water supply and sewerage and plumbing systems.

NPT and BSP threads, already mentioned, are examples of pipe threads.

JIC thread

Joint Industry Council (JIC) fittings are a type of socket fitting with a socket surface made in the shape of a 37° cup. JIC fittings are defined by SAE J514 and MIL-DTL-18866 standards and are used in fuel delivery and fluid supply applications - especially where high pressure (up to 10,000 PSI) is involved

JIS thread

JIS thread is a standard thread type used in Japan and some Asian countries. JIS is short for "Japanese Industrial Standard".

JIS threads are similar to other thread types such as BSP and NPT, but there are some differences in shape and dimensions.

UNF thread

UNF threads are threads that have a fine pitch, meaning that they have more vertices per inch. In addition, UNF threads have less depth and are more prone to breakage. The side angle is 60°. UNF stands for "Unified National Fine".

They are commonly used in applications where a higher level of threaded connection and more precise adjustment is required.

UNC thread

UNC threads are threads that have a large pitch, meaning that there are fewer vertices per inch. In addition, UNC threads have a greater depth and are more resistant to breakage. The side angle is 60°. UNC stands for "Unified National Coarse".

They are commonly used in applications requiring quick assembly and disassembly.

UNEF thread

UNEF is similar to the UNF thread, but has a narrower profile. This means a finer pitch, i.e. an even greater number of vertices per inch. The side angle of the UNEF thread is 60°, similar to other unified threads. UNEF thread stands for "Unified National Extra Fine".

It is used in applications requiring an even finer threaded connection and tighter tolerances, such as in industries such as aerospace.

UN thread

UN thread is the standard thread type used in the United States and other countries. The unified thread series is divided into coarse threads (UNC), fine threads (UNF) and extra fine threads (UNEF). UN stands for "Unified National".

UNS thread

UNS thread define a series of threads that have a uniform or constant number of vertices per inch (regardless of diameter), but do not fall within the parameters of UNC or UNF. UNS stands for "Unified National Special".

ACME thread

The ACME thread is a type of trapezoidal thread that provides better strength than V-shaped threads and is easier to produce than square threads. It is commonly used in applications requiring high torque and power transmission.

There are three main classes of Acme threads:

- General purpose (G),

- Centralising (C),

- Acme Stub.

G-thread – BSPP thread

G-Threads and BSPP Threads are cylindrical threads used for pipe connections. They form part of the British Standard Pipe and are widely used in Europe and other countries where this standard is popular.

R-thread – BSPT thread

R-Threads and BSPT Threads are tapered threads used for pipe connections. They form part of the British Standard Pipe and are widely used in Europe and other countries where this standard is popular.

NPTF thread

NPTF thread is similar to an NPT thread, but differs slightly in shape and dimensions.

In addition, NPTF threads do not require a sealant to prevent leakage. Therefore, they are used in applications that require tightness without the use of PTFE tape or other similar compounds.

Popular use cases for NPTF threads include hydraulic and pneumatic systems, as well as fuel systems. NPTF stands for "National Pipe Tapered for Fuels".

SAE thread

The SAE thread is a type of thread used in automotive and other low-pressure applications. It requires an additional O-ring, seal or sealing surface to form a seal, but is highly reliable and reusable. SAE is an abbreviation for "Society of Automotive Engineers".

SAE threads are defined by the SAE J514 standard.

ORFS thread

ORFS threads are threads used in hydraulic fittings for high-pressure applications. They provide a tight connection by using an O-ring groove on the flat surface of the fitting. ORFS stands for O-Ring Face Seal.

ORFS threads are available in a variety of types and are used in industries where a reliable seal is required.

BSF thread

The BSF thread is a fine thread alternative to the BSW (British Standard Whitworth) thread with the same angle. They were widely used in the automotive industry and other applications requiring fine pitch threads. BSF is short for British Standard Fine.

BSF threads are part of the British Standard Threads and are defined by British Standard BS 84 - 2007.

BSW thread

The BSW thread is a long-stroke thread that was proposed by Sir Joseph Whitworth in 1841 and was the first standardised thread. It is widely used in the automotive industry and other applications requiring long pitch threads. BSW is short for British Standard Whitworth.

BSW threads are part of the British Standard Threads and are defined by British Standard BS 84 - 2007.

Edison thread

Edison thread refers to the standard electric bulb holder that was developed by Thomas Edison, patented in 1881 and licensed in 1909 under General Electric's Mazda trademark.

The Edison thread has become the international standard for light sockets. It is also widely used in the automotive industry and other applications requiring a long pitch thread.

Pg thread

Pg threads are German cylindrical threads with a shallower thread depth and a greater angle of outline. They were commonly used in cable glands and electrical applications. Pg stands for Panzer-Gewinde.

Currently, Pg threads are being phased out in favour of the new metric thread standard in continental Europe.

Tr thread

The Tr - trapezoidal symmetrical thread is a type of thread defined in ISO:2901/2/4 and used in various countries around the world. Like ACME threads, trapezoidal threads are trapezoidal with a 29° angle. They are commonly used in applications that require linear movement, such as set screws, power transmission systems and heavy-duty machinery.

Rp thread

The Rp thread is a cylindrical Whitworth internal pipe thread in accordance with DIN/ISO 2999. It connects to the tapered R external thread.

Rc thread

The Rc thread is also a Whitworth internal pipe thread, but tapered. Like the Rp thread, it connects to the tapered R external thread.

NC thread

The NC thread is a special thread for electrical installations. It is used for steel pipes and electrical installations.

RD thread

The RD thread is a round, external thread. It is characterised by high static and fatigue strength.

S-thread

The S-thread is an asymmetrical trapezoidal thread. It is used, among other things, in screws for lifting equipment.

Ven thread, VG thread

Ven and VG threads are valve threads. Their side angles are 60°. In addition, they carry numerical designations, e.g. Vg 8.

They are primarily used for car tyres.

W thread

The W thread is a tapered thread for gas cylinders and valves. Its forming angle is 55°.

How to check whether a thread is metric or inch?

To check whether a thread is metric or inch, you need the pitch and the outside diameter (for a screw thread) or the inside diameter (for a nut thread).

The pitch of a thread is the distance from one vertex to the other in mm (for the metric system) or the number of tips per inch (for inch threads).

First, measure the diameter of the thread using a calliper. Then match it to the corresponding thread using the dimension chart. The diameter indicates whether the thread is metric or inch.

Then use a thread template (comb) and check which one fits. Read the pitch from the tool, and you will know exactly what thread you have in hand.

Which thread has the highest efficiency?

The square thread has the highest efficiency. It has a much higher internal efficiency than trapezoidal threads. As it features a zero profile angle, the nut bursting pressure is minimal. In addition, the square thread provides better power transmission.

However, the downside is that square threads cannot carry as high loads as trapezoidal threads. In addition, there is no way to compensate for wear on the nut, so it has to be replaced when it wears out.

What are inch threads?

Well, there are different inch threads. The most common types are UNC, UNF, NPT, BSP or SAE.

What is the difference between an R thread and a G thread?

An R thread differs from a G thread in that it is tapered. In contrast, G is a cylindrical thread.

How to read thread markings?

Read the thread markings as follows. First, determine whether the thread is metric or inch. Metric threads are identified by the capital letter "M" followed by the nominal diameter and pitch (e.g. M22x1.5). Inch threads, on the other hand, are defined by the nominal diameter and the number of vertices per inch (e.g. 1/4-20).

Also consider that different thread standards have specific designations and standards.

How to identify left-hand thread?

To distinguish a left-hand thread, look for the letters "LH" in the designation (e.g. TR20x4-LH). You can also determine the direction of the thread by checking it visually. If you look at the screw in profile, you will see the difference between left-hand and right-hand threads. For left-hand threads, the vertices rise from the lower right-hand corner to the upper left-hand corner.

How to choose a thread for a bolt?

To select a thread for a bolt, pay attention to several key factors, such as thread size and type, strength, material or load.

How many types of threads are there?

There are many types of threads, which can be classified on the basis of their characteristics, such as nominal diameter, pitch or shape. In this article, we have described all the most common thread varieties.

What is the standard thread used in Europe?

The standard thread used in Europe is the metric thread. Its most common standards are ISO and DIN.

Which thread is the strongest?

The strongest thread in many cases is the trapezoidal thread. However, take into account that the choice of the right thread largely depends on the application and the necessary features.

Which thread is the weakest?

It is difficult to determine unequivocally which thread is the weakest. The strength of a thread depends on various factors, such as material, thread type and application.

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

What is a thread?

Shape-based thread classification

Symmetrical trapezoidal thread

Unsymmetrical trapezoidal thread

Round thread

Rectangular thread

Triangular thread

Classification of threads according to their placement

External thread

Internal thread

Classification of threads according to the measurement system

Metric thread

Inch thread

Classification of threads according to inclination

Tapered thread

Cylindrical thread

Classification of threads according to rotation direction

Right-hand thread

Left-hand thread

Classification of threads according to pitch

Fine thread

Coarse thread

Normal thread

Popular thread standards

NPT thread,

BSP thread

Whitworth thread

Pipe thread

JIC thread

JIS thread

UNF thread

UNC thread

UNEF thread

UN thread

UNS thread

ACME thread

G-thread – BSPP thread

R-thread – BSPT thread

NPTF thread

SAE thread

ORFS thread

BSF thread

BSW thread

Edison thread

Pg thread

Tr thread

Rp thread

Rc thread

NC thread

RD thread

S-thread

Ven thread, VG thread

W thread

How to check whether a thread is metric or inch?

Which thread has the highest efficiency?

What are inch threads?

What is the difference between an R thread and a G thread?

How to read thread markings?

How to identify left-hand thread?

How to choose a thread for a bolt?

How many types of threads are there?

What is the standard thread used in Europe?

Which thread is the strongest?

Which thread is the weakest?

See also other categories