How does a chiller work? Water chiller principle of operation

How does a chiller work?

The chiller works on the principle of the refrigeration cycle. Although there are many different chillers, most of them use the same method of removing high temperatures.

An important part of the process is the aforementioned refrigerant, which retains more heat than water or air. In this way, it helps to maintain stable thermal conditions.

The chiller concept is based on the principle that cooling involves removing heat from the process and releasing it into the air.

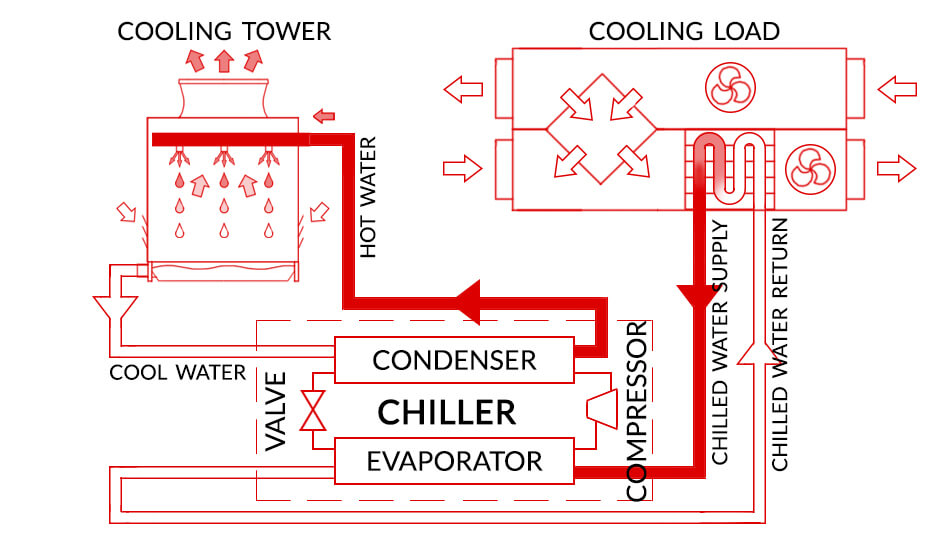

Almost all chillers have a condenser, a compressor, an expansion valve and an evaporator. A refrigerant circulates between them in coolant hoses. The chiller converts it from liquid to vapour and then back to liquid.

In its vapour form, the refrigerant removes heat from the process. On the other hand, when it returns to liquid form via the compressor and condenser, the refrigerant starts another cycle in the system to recover heat from the process or operation.

What is a refrigeration cycle?

The refrigeration cycle is a very simple but extremely clever and useful process. In its most basic form, it consists of four components that form a closed circuit:

- a compressor,

- a condenser,

- an expansion device,

- an evaporator.

The last element in the cycle is the refrigerant. It circulates in the cycle and dissipates heat.

The cycle starts in the compressor, which compresses the refrigerant and distributes it around the circuit. Further on, the condenser cools the refrigerant and turns it into a vapour and then into a liquid.

The job of the expansion unit is to reduce the pressure so that the refrigerant is more easily converted to a gaseous state in the evaporator. From there, the refrigerant is returned to the compressor and the cycle starts again.

The refrigerant in the circuit is both a gas, a vapour and a liquid. It is this change in its state of aggregation that causes the cooling effect and is the main principle of the refrigeration cycle

What does the chiller's performance depend on?

The performance of a chiller depends on many factors, such as its type and size, the thermal conditions of the environment or the desired process temperature.

Cooling capacity measures the ability of a cooling system to remove heat. Its SI units are watts (W), but it can also be expressed in British thermal units per hour (BTU/h) or tons of refrigeration (RT).

The chiller performance decreases as the setpoint temperature is reduced. When the desired value is lower, the temperature difference between the refrigerant and the liquid in the chiller is lower. As a consequence, the heat transfer efficiency decreases, resulting in a reduction in chiller performance.

Therefore, the manufacturer's specifications for a given unit often indicate the performance of the chiller at a certain temperature.

As we have already mentioned, chiller performance is also affected by ambient thermal conditions (or water temperature in the case of water-cooled units). Heat removal will be hindered at higher air or water temperatures.

Ultimately, efficiency is also affected by maintenance. If the chiller is dirty or in poor condition, its efficiency will decrease.

FAQ

Are chillers environmentally friendly?

Chillers can be environmentally friendly, but this depends on several factors. It is primarily about the type of refrigerant and energy consumption. If you choose a unit with a refrigerant that is less harmful to the environment and energy-efficient, you will reduce your carbon footprint and limit the production of greenhouse gases.

What is the ideal chiller temperature?

The ideal chiller temperature depends on the application. For example, chillers used in data centres maintain temperatures below 20 degrees Celsius, while in food production it is below 4 degrees Celsius.

How long do chillers last?

Generally, chillers last between 15 and even 30 years. However, their lifespan is influenced by many factors, such as the type of chiller, the quality of construction and regular maintenance. By taking care of the individual components of your chiller, you can significantly extend its service life.

Summary

Chillers operate using a four-stage process: evaporation, compression, condensation and expansion. The refrigerant that they contain passes through each phase to absorb heat from the air or water and release it into the atmosphere.

This type of equipment is an essential part of many HVAC systems and plays an important role in manufacturing processes as well as public buildings.

Knowing how chillers work will not only make it easier for you to select the right unit, but also to operate it.

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

How does a chiller work?

What is a refrigeration cycle?

What does the chiller's performance depend on?

FAQ

Are chillers environmentally friendly?

What is the ideal chiller temperature?

How long do chillers last?

Summary

See also other categories