HNBR rubber - Hydrogenated nitrile rubber - definition, production, properties, applications

Looking for an affordable rubber that can withstand the heat, chemical exposure and harsh environments of your industry? HNBR hydrogenated nitrile rubber will be perfect for this role. In this article, we will delve into the topic of HNBR rubber.

What is HNBR rubber?

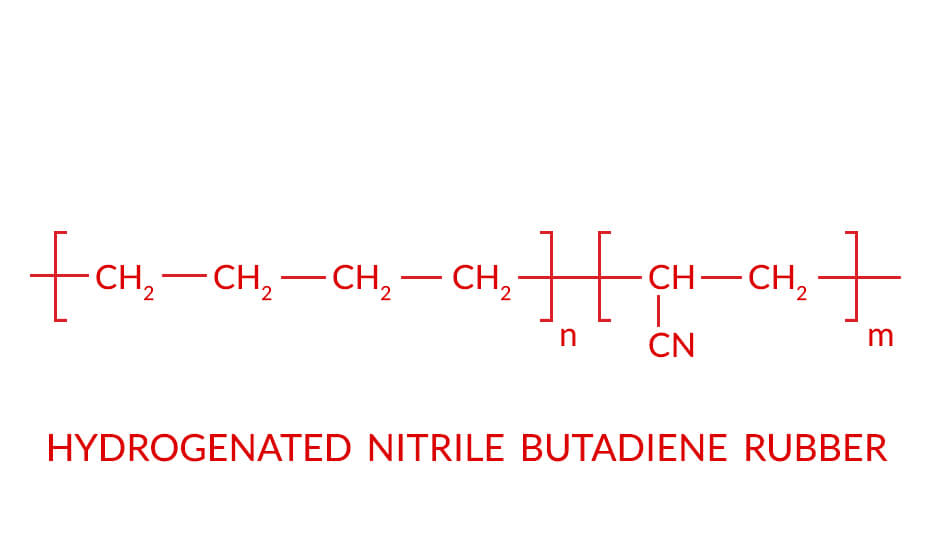

HNBR rubber is a special class of nitrile rubber – NBR rubber - that has been hydrogenated to increase the saturation of the butadiene segment in the carbon polymer backbone.

This results in better material properties that include greater thermal stability, broader chemical resistance and better tensile strength.

Nevertheless, HNBR is still a type of hydrocarbon rubber. It should not be expected to provide the same chemical resistance or thermal stability as fluorine rubbers.

What does HNBR stand for?

HNBR stands for "Hydrogenated Nitrile Butadiene Rubber", i.e. hydrogenated nitrile butadiene rubber. This type of rubber is also referred to by the abbreviation HSN ("Highly Saturated Nitrile").

How is HNBR rubber produced?

HNBR rubber is produced by hydrogenating NBR. This results in the removal of olefin groups, which are susceptible to degradation by various chemicals as well as ozone.

Usually, a Wilkinson catalyst is used for hydrogenation. The nitrile groups remain intact.

The hydrogenation degree also determines the type of vulcanisation that can be applied to the polymer.

Who manufactures HNBR rubber?

HNBR rubber is produced by at least a few companies from around the world. The first is the Japanese Zeon Corporation, which produces the material under the trade name Zetpol. Another company is LG Chem, a South Korean giant producing rubber under the trade name Krynac. Lastly, Lanxess, a German company producing HNBR under the trade name Therban, is worth mentioning.

What are the properties of HNBR rubber?

The properties of HNBR rubber depend on the acrylonitrile content and the hydrogenation degree of the butadiene copolymer. HNBR rubber offers better resistance to oils and chemicals than nitrile rubbers. In addition, it can withstand significantly higher temperatures.

HNBR rubber has excellent resistance to oils and fuels, many chemicals, as well as heat (steam/hot water) and ozone, similar to NBR rubber.

Mechanical properties of HNBR rubber such as tensile, tear, and elongation strength or abrasion resistance are also excellent. Furthermore, HNBR has good dynamic properties at elevated temperatures.

On the other hand, disadvantages of HNBR rubber include a higher cost and limited resistance to aromatic oils and polar organic solvents, poor electrical properties, and poor flame resistance.

As with NBR, many properties can be influenced by changing the acrylonitrile content of the rubber. HNBR elastomers with a high nitrile content have better resistance to mineral oils, while peroxide/sulfur-cured HNBRs have the best compressive strength and heat resistance.

Is HNBR resistant to oil?

Yes, HNBR is oil resistant. The rubber can operate in contact with mineral oil-based hydraulic fluids, animal and vegetable fats, diesel and other oils.

Is HNBR ozone-resistant?

Yes, HNBR is ozone resistant. The polymer's unique structure and hydrogenation process make it highly insensitive to ozone, allowing it to maintain its integrity and performance in environments rich in this oxygen species.

Is HNBR compatible with methanol?

HNBR is reasonably compatible with methanol. However, it should be noted that the rubber experiences some side effects when exposed to methanol, such as partial loss of physical properties or swelling.

What is the temperature range of HNBR rubber?

The usual temperature range for HNBR rubber is -25°C to 150°C. However, it is worth noting that, in the short term, the material will withstand operating conditions as high as 190°C.

Special sulphur- or peroxide-cured grades have better dynamic properties, but also a lower maximum application temperature.

What is the maximum temperature for HNBR?

The maximum upper temperature for HNBR is approximately 150°C. However, some manufacturers specify resistance up to 165°C. It is also worth mentioning that, in the short term, rubber can also come into contact with higher temperatures (up to 190°C).

What are the applications of HNBR rubber?

The applications of HNBR rubber are seen wherever excellent performance is needed at a lower price than fluoroelastomers (FKM). The rubber fills the gap between NBR and FKM in many industries where resistance to both heat and aggressive media is required.

HNBR is an excellent option where resistance to ozone and weathering, industrial lubricants, amine-based corrosion inhibitors, acid gases (H2S), and hot water/steam up to 150°C are needed.

HNBR rubber is widely used in a variety of industries and is often used in oil and chemical systems - both dynamic and static. Typical HNBR products include o-rings, gaskets, and rubber hoses, as well as battery bladders and diaphragms.

What are the trade names of HNBR rubber?

Trade names of HNBR rubber are as follows:

- Zhanber,

- Therban,

- Zetpol.

Who invented HNBR rubber?

It is not clear who exactly invented HNBR rubber. What we do know, however, is that basic NBR rubber was developed in 1931 at BASF and Bayer, then part of the IG Farben chemical conglomerate. The first commercial production began in Germany in 1935.

HNBR elastomers, on the other hand, have been developed quite recently. Their main purpose is to improve the mechanical resistance of NBR rubbers while maintaining resistance to mineral oils.

What is the difference between NBR and HNBR?

The main difference between NBR and HNBR is that NBR is the non-hydrogenated form of rubber, whereas HNBR is hydrogenated. As a result, HNBR offers better resistance to oils and chemicals, as well as high temperatures.

Is Viton an HNBR?

No, Viton is not actually HNBR. Viton is classified as a fluorocarbon (FKM) and is a registered trademark of The Chemours Company

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

What is HNBR rubber?

What does HNBR stand for?

How is HNBR rubber produced?

Who manufactures HNBR rubber?

What are the properties of HNBR rubber?

Is HNBR resistant to oil?

Is HNBR ozone-resistant?

Is HNBR compatible with methanol?

What is the temperature range of HNBR rubber?

What is the maximum temperature for HNBR?

What are the applications of HNBR rubber?

What are the trade names of HNBR rubber?

Who invented HNBR rubber?

What is the difference between NBR and HNBR?

Is Viton an HNBR?

See also other categories