SBR Rubber - definition, production, properties, applications

SBR rubber is a material with practical properties such as resistance to abrasion, stretching and tearing. This makes it ideal for manufacturing tough and durable products.

In this article, we will take a closer look at SBR rubber in particular, its properties, applications, and production process.

What is SBR rubber?

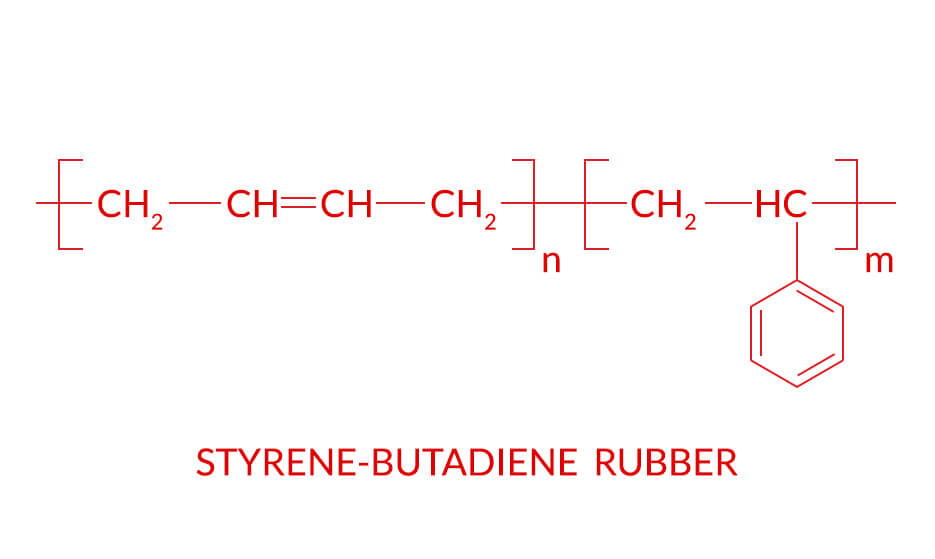

SBR rubber is a general-purpose synthetic rubber that is made from a copolymer of styrene and butadiene. It is currently produced in the largest quantities compared to other types of rubber.

In many cases, it is used as a cost-effective alternative to natural rubber.

What kind of rubber is SBR?

SBR is a type of synthetic rubber that is made from styrene and butadiene. It is characterized by good abrasion and aging resistance.

Is SBR rubber the same as latex?

No, SBR rubber is not the same as latex. Latex is a natural substance that plants (such as rubber trees) produce, but it can also be produced artificially. It is later made into rubber.

What does SBR stand for?

SBR stands for "Styrene-Butadiene Rubber".

How is SBR rubber produced?

SBR rubber is produced from 75% butadiene and 25% styrene. The molecules of the two monomers are combined to form long, multi-unit molecules in a process called copolymerization.

SBR copolymers are formed by an emulsion process in which a soap-like surfactant disperses or emulsifies monomers in aqueous solution.

Other materials in solution are:

- free radical initiators, which start the polymerization process,

- stabilizers that prevent deterioration of the final product.

After polymerization, repeating units of styrene and butadiene are randomly distributed along the polymer chain. They are then cross-linked during the vulcanization process.

Is SBR rubber vulcanized?

Yes, SBR rubber is vulcanized. Thanks to the vulcanization process, it hardens and acquires better physical properties.

What are the types of SBR rubber?

There are two types of SBR rubber: emulsion SBR and solution SBR.

Emulsion SBR

Emulsion SBR can be produced by free-radical emulsion polymerization of styrene and butadiene. This is done at a temperature of 50 to 60°C (hot SBR emulsion) or at about 5°C (cold SBR emulsion).

Emulsion SBR has been favored in the past because of its excellent processing properties and ability to be produced in a continuous process, making it extremely cost-effective.

The main properties of emulsion SBR are as follows:

- The raw strength decreases as the oil concentration increases;

- Low elasticity and low tensile strength;

- Exceptional abrasion resistance;

- Low resistance to oil, other hydrocarbon fluids and ozone;

- Hot polymers are difficult to machine due to low raw strength;

- Poor tear resistance;

- Resins with a high styrene content have good properties at low temperatures, but stiffen.

Solution SBR

Solution SBR can be produced using both batch and continuous processes, with the batch method allowing easier manipulation of reaction conditions and polymer characteristics.

An SBR solution is made by anionic polymerization (without termination) of a solution of styrene and butadiene with an alkyl lithium initiator (such as butyllithium). This is done in a hydrocarbon solvent, usually hexane or cyclohexane.

Among the main properties of solution SBR are:

- Better flexibility and performance;

- Good elasticity, tensile strength and low rolling resistance in tires;

- Excellent abrasion and fatigue resistance;

- Low resistance to oil, other hydrocarbon fluids and ozone.

What are the properties of SBR rubber?

The properties of SBR rubber start with very high elasticity. It is for this reason that many manufacturers use synthetic rubber instead of natural rubber.

In addition, SBR shows very good mechanical strength, especially against abrasion and tearing. The rubber is also insensitive to:

- inorganic acids and bases,

- water,

- alcohol,

- brake fluids (containing glycols).

In addition, it shows high resistance to compression, wear and tear. What's more, it retains its properties at low temperatures.

On the other hand, the downside of SBR is its sensitivity to:

- mineral oils and lubricants,

- gasoline,

- chlorinated hydrocarbons,

- aliphatic and aromatic hydrocarbons.

It also shows low resistance to ozone and solar radiation, which can negatively affect the structure or functionality of the rubber.

Equally important, SBR is a fairly good electrical insulator.

The rubber also has the unquestionable advantage of being relatively low cost. Combined with its high resistance and physicochemical functionality, this gives good value for money.

How long does SBR rubber last?

SBR rubber lasts for many years. The exact time depends on the type of elastomer and storage conditions such as temperature, humidity, ozone and exposure to light. The recommended shelf life of SBR rubber is 3 to 5 years. However, it is a storage-only issue and depends on conditions that can affect the quality and shelf life of rubber products.

If rubber products are stored under the most suitable conditions, they can be used throughout their shelf life and even beyond. Again, poor storage conditions can shorten the expected shelf life. If the shelf life has expired, rubber products should be carefully evaluated for their ability to be used for their original purpose before you decide to discard them based solely on their suggested shelf life.

Does SBR rubber crack?

SBR rubber is resistant to cracking over a wide temperature range.

Is SBR rubber biodegradable?

No, SBR rubber is not biodegradable. However, there are experiments that suggest that certain strains of bacteria can break down the chemical bonds of carbon and sulfur in vulcanized SBR in as little as four weeks! Meanwhile, it is worth mentioning that the level of degradability also depends on the rubber compound.

Is SBR rubber waterproof?

Yes, SBR rubber is waterproof.

Is SBR rubber resistant to UV radiation?

SBR rubber is not very resistant to UV radiation. This means that under its influence it can degrade and reduce its properties.

Is SBR rubber resistant to heat?

SBR rubber is moderately resistant to heat. The maximum permanent operating temperature of the rubber is 110°C.

Is SBR rubber polar or non-polar?

SBR rubber is non-polar.

What is the temperature range of SBR rubber?

The temperature range of SBR rubber is from -50°C to 110°C (briefly up to 120°C). Within this range, the rubber retains its properties and is suitable for continuous use.

At -60°C, SBR rubber begins to lose its elasticity and becomes brittle.

What are the applications of SBR rubber?

The applications of SBR rubber mainly relate to the production of automobile tires. The material is also a more economical alternative to natural rubber.

That's why SBR rubber is found in everything from the soles and heels of our shoes, to rubber drive couplings, gaskets, rubber hoses, cable insulation, conveyor belts and even chewing gum.

SBR rubber is also used in latex form as an adhesive.

What are the trade names of SBR rubber?

Trade names of SBR rubber are as follows:

- Buna EM,

- Europrene,

- Cariflex,

- Polysar S,

- Krylene.

Some manufacturers use it instead of the technical abbreviation that refers to rubber components.

Who invented SBR rubber?

SBR rubber was invented by Walter Bock and Eduard Tschunkur of IG Farben. They first developed the production method in Germany in the 1930s. It was then that they polymerized a synthetic rubber called Buna-S from butadiene and styrene in an aqueous emulsion.

In the 1960s, Firestone and Phillips began commercial production of the first random SBR grades polymerized in solution.

What are the disadvantages of SBR rubber?

The disadvantages of SBR rubber are as follows: poor resistance to strong acids, ozone, oils, oil esters, fats, gasoline and most hydrocarbons. Excessive sunlight can also adversely affect the structure of the rubber.

What is the difference between SBR and rubber?

The difference between SBR and rubber is that SBR has better water resistance, heat and abrasion resistance, low-temperature flexibility, and longevity. In addition, SBR has better ozone resistance and is cheaper than natural rubber.

In addition, the properties of both materials are very similar.

What is the difference between SBR rubber and EPDM rubber?

The difference between SBR rubber and EPDM is as follows: SBR is considered a relatively inexpensive rubber that is used where high abrasion resistance is needed. EPDM, on the other hand, is a more expensive rubber used in applications requiring excellent weather, ozone and UV resistance.

Why is SBR rubber better than natural rubber?

SBR rubber is better than natural rubber for several reasons. First of all, it is more flexible and resistant to external agents such as water, salt solutions, low concentration inorganic acids and bases, alcohols and glycol-based brake fluids. Moreover, SBR rubber is more readily available and less expensive.

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

What is SBR rubber?

What kind of rubber is SBR?

Is SBR rubber the same as latex?

What does SBR stand for?

How is SBR rubber produced?

Is SBR rubber vulcanized?

What are the types of SBR rubber?

Emulsion SBR

Solution SBR

What are the properties of SBR rubber?

How long does SBR rubber last?

Does SBR rubber crack?

Is SBR rubber biodegradable?

Is SBR rubber waterproof?

Is SBR rubber resistant to UV radiation?

Is SBR rubber resistant to heat?

Is SBR rubber polar or non-polar?

What is the temperature range of SBR rubber?

What are the applications of SBR rubber?

What are the trade names of SBR rubber?

Who invented SBR rubber?

What are the disadvantages of SBR rubber?

What is the difference between SBR and rubber?

What is the difference between SBR rubber and EPDM rubber?

Why is SBR rubber better than natural rubber?

See also other categories