22 Different Types of Rubber

Rubber is a fascinating and versatile material that we encounter in everyday life more often than we think.

But did you know that there are different types of rubber, each with its own unique properties and uses? In this article, we introduce you to the world of rubber materials and delve into their different types.

What are the types of rubber?

The most popular types of rubber are:

- NR rubber – Natural rubber,

- Synthetic rubber,

- Vulcanised rubber,

- CSM Rubber – Chlorosulphonated polyethylene,

- Neoprene rubber – CR rubber,

- Silicone rubber,

- NBR rubber,

- EPDM rubber,

- SBR Rubber,

- Butyl Rubber – IIR Rubber,

- Fluorosilicone rubber – FVMQ rubber,

- Polyurethane rubber,

- Epichlorohydric rubber,

- Hydrogenated nitrile rubber – HNBR rubber,

- Viton rubber – FKM rubber,

- AEM rubber – Ethylene acrylic rubber,

- Teflon – PTFE,

- ACM Rubber – Acrylic Rubber,

- EU Rubber – Urethane/polyether rubber,

- CIIR Rubber – Chlorobutyl rubber,

- BR Rubber – Butadiene rubber,

- EPM Rubber – Ethylene-Propylene Rubber,

- Polyvinyl chloride – PVC.

Natural rubber (NR rubber)

Natural rubber is a type of rubber that is derived from the milky liquid (latex) found in the Hevea brasiliensis tree. It consists of polymers of the organic compound isoprene and small impurities in the form of other organic compounds.

Some of the key characteristics of the material include high tear and tensile strength, resilience and resistance to abrasion, friction, extreme temperatures, and swelling in water.

Typical applications for natural rubber include adhesives, flooring, roofing, gloves, insulation and tyres.

Synthetic rubber

Synthetic rubber is an artificially produced material that imitates the desired properties of natural rubber. We are dealing with a polymer or artificial polymer, which means that it consists of long chains of repeating units called monomers (usually petroleum-based).

Synthetic rubber comes in many versions and types. As a result, it offers a wide range of properties and use cases, with which it complements the use of natural rubber in various industries.

Vulcanised rubber

Vulcanised rubber is any type of rubber that has been cured by a process known as vulcanisation. By exposing the rubber to heat and sulphur, new cross-links are formed in the structure of the material. As a result, a stronger and more flexible rubber is produced.

Vulcanised rubber is used in a variety of products, including rubber hoses, shoe soles, toys, rubbers, hockey pucks, shock absorbers, conveyor belts, grips/vibration dampers, insulation materials, tyres or bowling balls.

Most rubbers undergo a vulcanisation process as it significantly improves the life, functionality and durability of the material.

CSM Rubber - Chlorosulphonated polyethylene

CSM rubber is a synthetic rubber based on polyethylene. It is also known as Hypalon, which is DuPont's proprietary trade name for CSM.

CSM rubber has better thermal and chemical resistance than chloroprene rubber (CR) due to the presence of chlorine. It is a flexible, vulcanisable rubber that provides excellent resistance to ozone, oxidation, sunlight and weathering. It is also able to provide excellent alkali and acid resistance.

CSM rubber is also insensitive to oils and has low gas permeability.

However, it has poor/moderate fuel resistance and its low temperature properties are generally limited (depending on the chlorine content).

The material is often used in electrical applications and as protective coatings against corrosive environments. In addition, excellent UV resistance makes the rubber suitable for outdoor applications.

Neoprene rubber – CR rubber

Neoprene rubber is one of the oldest types of synthetic rubber. Compared to other types of rubber, it shows extremely low susceptibility to burning, corrosion and degradation. This makes it an ideal base material for adhesives and corrosion-resistant coatings.

What's more, its ability to maintain good mechanical properties over a wide temperature range also makes it suitable for use in high-pressure gaskets, belts and window and door seals.

Silicone rubber

Silicone rubber is a popular type of rubber known for its plasticity, biocompatibility and resistance to extreme temperatures, fire, ozone and ultraviolet (UV) radiation. It is available in both solid and liquid forms in a variety of colours.

The chemically inert nature of silicone rubber makes it ideal for use in parts and products requiring biocompatibility (such as gloves, respirators, implants and other medical products) and chemical resistance (such as baby care items, cosmetic applicators and food containers and instruments).

NBR rubber

NBR rubber is a type of rubber that exhibits several desirable mechanical and chemical properties, such as resistance to compression, heat, oil and gas, as well as wear. These properties make it suitable for use in automotive gaskets and seals, O-rings and engine hoses.

It is also used in medical products (e.g. surgical gloves) because it does not contain the allergenic proteins of latex-based rubbers and maintains structural integrity better than silicone rubber.

EPDM rubber

EPDM rubber is a synthetic rubber with excellent durability, resistance to damage and insensitivity to degradation in extreme temperatures and weather conditions.

These properties make it suitable for use in exterior parts and products such as roof sealants, rubber hoses, and gaskets. Meanwhile, the excellent sound and thermal insulation properties also make EPDM rubber suitable for use in automotive systems.

SBR Rubber

SBR rubber is a copolymer of styrene and butadiene that has excellent hardness and durability. It shows better resistance to abrasion, alcohol, compression and swelling than some of the more expensive synthetic rubbers, making it ideal for use in seals integrated into hydraulic brake systems.

Other common applications include cutting boards, various seals and shoe soles.

Butyl Rubber - IIR Rubber

Butyl rubber is a unique rubber that provides one of the highest levels of gas impermeability. This characteristic, combined with the material's excellent elasticity, makes it suitable for the manufacture of airtight components such as inner tubes, sports balls, and sealants.

As a liquid compound, it is also often used as an additive in diesel and petroleum-based fuels and chewing gums.

Fluorosilicone rubber – FVMQ rubber

Fluorosilicone rubber is an industrial rubber that is highly resistant to extreme temperatures (-70°C to 175°C), transmission fluids, oil and petroleum-based fuels, synthetic lubricants, fire, and ozone. These properties make it an ideal material for aircraft fuel systems and other highly specialised industrial applications.

Polyurethane rubber

Polyurethane rubber is a strong rubber with a considerable resistance to abrasion and extrusion. However, o-rings made from polyurethane are not suitable for applications requiring good compression and high temperature resistance. This is due to the narrower operating temperature range of -54°C to 100°C.

Polyurethane O-rings are often used in hydraulic fittings, actuators, valves and pneumatic tools.

Epichlorohydric rubber - ECH Rubber

Epichlorohydrin rubber is a synthetic type of rubber that is highly resistant to water, chemicals and heat. It is renowned for its good electrical insulating properties and low gas permeability.

ECH rubber is used in a wide variety of applications, including seals, gaskets and hoses in the automotive and aerospace industries, as well as in the manufacture of adhesives and coatings. It is also used as a matrix material in the production of composite materials.

HNBR rubber - Hydrogenated nitrile rubber

HNBR rubber is a type of nitryl rubber that shows better resistance to oils and chemicals than traditional nitrile rubber. In addition, HNBR rubber can withstand significantly higher temperatures.

HNBR rubber provides excellent resistance to oils, fuels, many chemicals, steam and ozone. It also offers exceptional tensile and tear strength, elongation and abrasion resistance. However, it is relatively expensive and offers limited flame resistance, poor electrical insulation and is not compatible with aromatic oils and polar organic solvents.

HNBR rubber is used in the automotive industry and in the manufacture of a wide range of components, including, for example, static seals, hoses and belts.

Viton rubber – FKM rubber

Viton rubber is a strong synthetic rubber that offers exceptional temperature stability from -45°C to 204°C.

Its disadvantages, however, are that it can swell in fluorinated solvents, is relatively expensive and can quickly fail if the wrong grade is used.

Along with nitrile, it is one of the most popular elastomers used for sealing applications, including O-rings and gaskets.

AEM rubber - Ethylene acrylic rubber

AEM rubber is a valuable type of rubber that retains good properties at low temperatures and has swelling resistance in non-polar oils. It also has good resistance to heat, ozone (weathering) and many chemicals.

AEM also has exceptional vibration damping and good dynamic and abrasive properties over a wide temperature range.

However, resistance to water and moisture is only good, as is resistance to diluted acids and alkalis. Moreover, AEMs are significantly more expensive than most standard elastomers.

Teflon (PTFE)

Teflon is a synthetic fluoropolymer of tetrafluoroethylene. It is considered a versatile material with a wide range of applications and is renowned for its non-stick properties. PTFE stands for polytetrafluoroethylene

Importantly, PTFE is a hydrophobic synthetic fluoropolymer that is completely resistant to moisture.

The material has many distinct advantages over elastomers, including corrosion resistance, a huge operating temperature range and an exceptionally smooth surface. It is also chemically resistant and inert, making it an ideal material for sealing components in chemically aggressive applications.

PTFE is not particularly expensive and has one of the best performance-to-price ratios among fluoropolymers.

ACM Rubber - Acrylic Rubber

ACM rubber is a specialised elastomer designed for high resistance to fuel and oil. Because of this, it is rarely used for general applications.

It has excellent resistance to ozone, heat and oil, making it ideal for engine blocks.

ACM gaskets, O-rings and belts are found in most high-temperature automotive engine sections. Rubber can also be used as a component of industrial grade gaskets and protective coatings.

EU Rubber - Urethane/polyether rubber

There are two main chemical compounds of moulded polyurethane: polyester (AU) and polyether (EU). The physical properties of these polymers show excellent tensile, abrasion and tear strength.

Polyurethane rubber is a versatile material that combines the flexibility of rubber with the strength of metal and ceramics.

Its properties are superior to plastic, rubber and metal as it is resistant to abrasion, heat, oil, solvents and various chemicals. This makes the material the choice of specialists designing products for heavy-duty and stressed applications.

Permeability is good and similar to that of butyl rubber.

Polyurethane rubber performs well in the temperature range from -50°C to 80°C. It is not compatible with esters, ketones, alcohols, acids, bases, amines, hot water and steam.

CIIR Rubber – Chlorobutyl rubber

CIIR rubber is a copolymer of isobutylene and isoprene. It is formed by reacting butyl rubber with chlorine in a continuous process.

Compared to regular butyl rubber, chlorobutyl rubber provides better compressive strength and better resistance to heat, ozone and bending fatigue.

BR Rubber - Butadiene rubber

BR rubber is a synthetic rubber widely used in truck and passenger car tyre treads. It is composed of polybutadiene, an elastomer made by chemically combining multiple butadiene molecules into large molecules or polymers.

The material is distinguished by its high abrasion resistance, low heat accumulation and resistance to cracking.

Most of the butadiene rubber produced is blended with natural rubber (polyisoprene) or styrene-butadiene rubber to give it better resilience and lower rolling resistance.

More than half of all uses are tyres. Other use cases include footwear, wire and cable insulation and conveyor belts.

Polybutadiene is also processed with styrene monomer to produce high-impact polystyrene and with styrene and acrylonitrile monomer to produce a high-performance plastic known as acrylonitrile-butadiene-styrene copolymer.

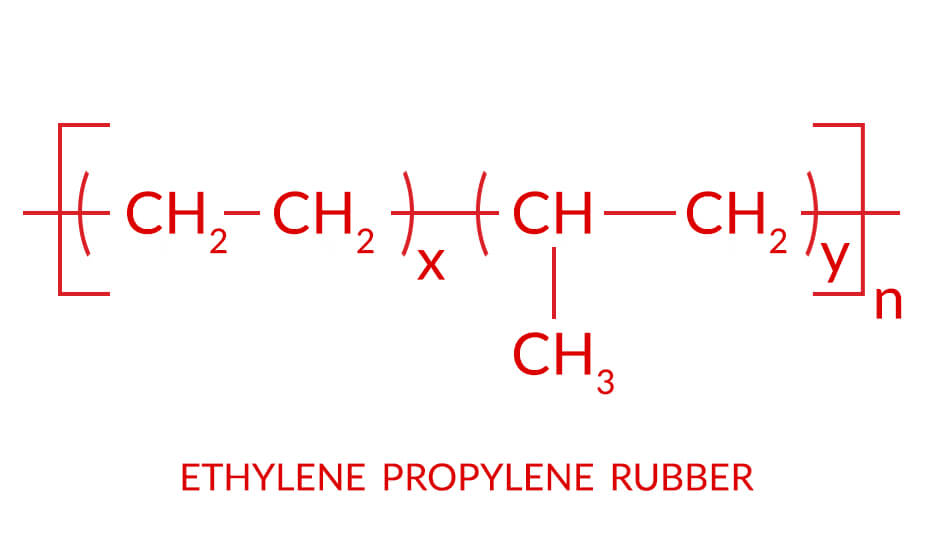

EPM Rubber - Ethylene-Propylene Rubber

EPM rubber is a type of synthetic rubber that is closely related to EPDM rubber.

EPM rubber is a valuable elastomer due to its useful chemical and physical properties. It is characterised by resistance to heat, oxidation, ozone and atmospheric conditions (thanks to its stable, saturated base), and is not prone to colour loss.

As a non-polar compound, EPM rubber is an electrical resistor and is insoluble in many polar solvents (both protonic and aprotic). Amorphous forms of EPM rubber are flexible at low temperatures (with glass transition points around -60°C).

By choosing certain sulphur compounds, EPM rubber can remain heat resistant up to 130°C and even up to 160°C when cured with peroxide.

EPM rubber is used in electrical cable insulation and in many flexible rubber products such as hoses or seals.

Polyvinyl chloride (PVC)

PVC is a thermoplastic material that can act as rubber. It is formed by the chlorination of hydrocarbon polymers to produce vinyl chloride monomer.

As a polymer, PVC can then be mixed with additives such as plasticisers and dyes to transform it into various forms of rigid and flexible plastic.

The material is distinguished by its excellent or very good resistance to acids, alkalis, UV radiation, ozone, flames, aliphatic hydrocarbons and other substances. PVC is also resistant to greases, oils, chemicals and general atmospheric conditions.

It also remains flexible over a wide temperature range.

How many types of rubber are there?

There are many different types of rubber. We have listed more than 20 of them in the article, and yet we still haven't exhausted the subject.

What type of rubber is the strongest?

No one type of rubber is the strongest in a general sense. Different rubber compounds and varieties have been developed with specific applications in mind. This is why some rubbers (e.g. natural) have very good physical properties, while others excel in their resistance to particular chemicals.

Is PVC rubber?

No, PVC is not rubber. It is a type of plastic made from vinyl.

What type of rubber is hard?

A hard type of rubber is, for example, ebonite (also known as "hard rubber"). It is formed by vulcanising natural rubber over a long period. Another example of hard rubber is SBR.

Can rubber be bulletproof?

No, rubber cannot be bulletproof. There are indeed varieties of rubber that are used to stop bullets (e.g. at a shooting range), but these are not considered bulletproof.

Which rubber is the best quality?

Best quality rubber is a material that is suitable for a specific application. Always choose the type of rubber based on criteria such as resistance to heat, chemicals, abrasion, weathering, etc.

Consulting experts or rubber manufacturers can provide more detailed information on the best types of rubber for specific applications.

Is rubber susceptible to fire?

Rubber can be susceptible to fire. However, many types of rubber are specially blended to be fire-resistant or flame-retardant. Some examples of such materials are silicone rubber, neoprene rubber, or FKM.

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

What are the types of rubber?

Natural rubber (NR rubber)

Synthetic rubber

Vulcanised rubber

CSM Rubber - Chlorosulphonated polyethylene

Neoprene rubber – CR rubber

Silicone rubber

NBR rubber

EPDM rubber

SBR Rubber

Butyl Rubber - IIR Rubber

Fluorosilicone rubber – FVMQ rubber

Polyurethane rubber

Epichlorohydric rubber - ECH Rubber

HNBR rubber - Hydrogenated nitrile rubber

Viton rubber – FKM rubber

AEM rubber - Ethylene acrylic rubber

Teflon (PTFE)

ACM Rubber - Acrylic Rubber

EU Rubber - Urethane/polyether rubber

CIIR Rubber – Chlorobutyl rubber

BR Rubber - Butadiene rubber

EPM Rubber - Ethylene-Propylene Rubber

Polyvinyl chloride (PVC)

How many types of rubber are there?

What type of rubber is the strongest?

Is PVC rubber?

What type of rubber is hard?

Can rubber be bulletproof?

Which rubber is the best quality?

Is rubber susceptible to fire?

See also other categories