EPDM rubber - definition, production, properties, applications

What is EPDM rubber?

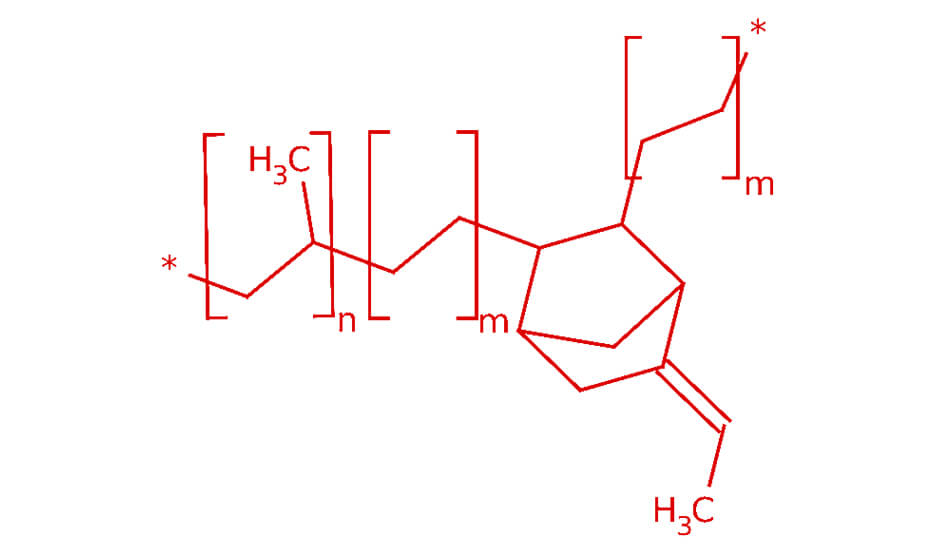

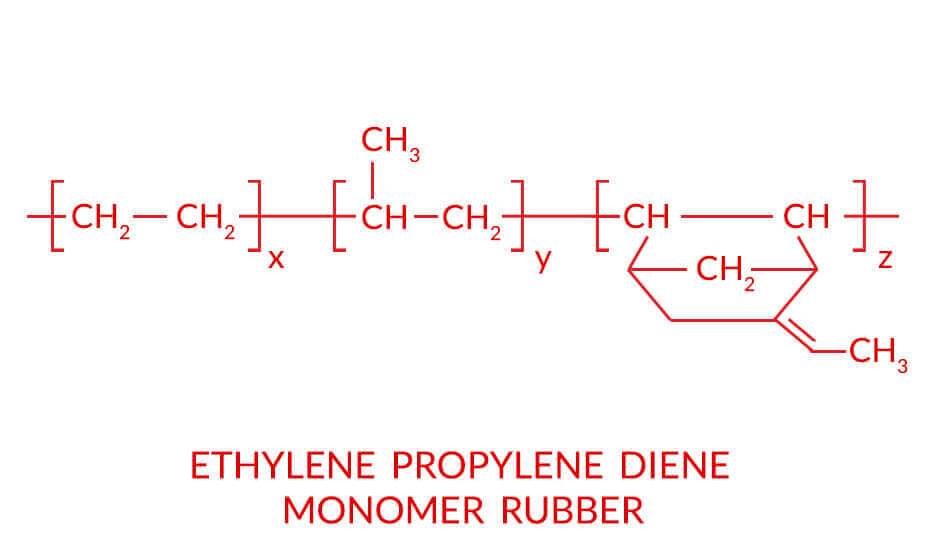

EPDM rubber is an ethylene-propylene-diene rubber, which is classified as a terpolymer due to its structure.

The ethylene content of the material is typically between 45% and 75%. On the other hand, the dienes monomers, although only a small part of the composition, provide cross-linking, which gives the final material its incredible elasticity, flexibility and durability.

It is worth knowing that the common name for EPDM is: "synthetic rubber” and this is no coincidence.

EPDM is an alternative to the natural rubber extracted from various tree species. However, the natural raw material is a severely limited resource (especially compared to global demand), so manufacturers began looking for an artificial substance with similar properties.

This need led to the development of synthetic rubber, which is known in the industry as EPDM type of rubber.

Its appropriate treatment and chemical composition make it extremely leak-proof. It also has excellent elasticity and tensile strength.

What does EPDM stand for?

EPDM is the English abbreviation for "ethylene propylene diene monomer (rubber)".

How is EPDM rubber produced?

EPDM rubber is produced from ethylene, propylene and diene comonomer, which allows cross-linking through sulphur vulcanisation.

As with most rubbers, EPDM is always used in combination with fillers such as carbon black or calcium carbonate, as well as plasticisers (e.g. paraffin oils). Furthermore, it only has functional rubber properties after cross-linking.

Cross-linking is mainly done by the aforementioned vulcanisation with sulphur, but is also carried out with peroxides (for better heat resistance) or phenolic resins. Furthermore, high-energy radiation is also sometimes used to produce EPDM foams, wires and cables.

What are the properties of EPDM rubber?

The properties of EPDM rubber are as follows:

- very high resilience while maintaining durability,

- resistance to mechanical damage,

- high resistance to UV radiation,

- ability to maintain the same properties over many years of use,

- insensitivity to microorganisms,

- resistance to hot water, brake oils, acids, alkalis and many other substances.

In addition, one of the main advantages of EPDM is its good reversible deformation capacity. This means that the structure of the material returns to its original shape even when high mechanical forces have acted on it.

This property remains constant at temperatures from -40 to 110 degrees Celsius. However, there are also more robust EPDM rubbers that retain their properties even at 180 degreesCelsius.

Furthermore, EPDM rubber is biologically and chemically dead. As a result, it is regarded as an environmentally friendly material that does not endanger the environment.

However, EPDM also has its disadvantages. Although it is a very versatile rubber, it cannot be used in every situation, as it is susceptible to the effects of:

- aliphatic and aromatic hydrocarbons,

- di-ester based lubricants,

- halogenated solvents,

- petroleum-based oils and greases.

It also has no resistance to hydrocarbon fluids, so there is a risk of corrosion if it comes into contact with them. Therefore, the material will not be a good choice for oil and gas applications.

Is EPDM rubber durable?

Yes, EPDM rubber is durable, especially against weather conditions, ozone and UV radiation.

How long will the EPDM rubber last?

EPDM rubber will last a very long time. Its lifespan often exceeds 20 years, especially when properly installed and maintained.

How long does EPDM rubber last in the sun?

EPDM rubber lasts a very long time in the sun. The rubber is extremely UV resistant, so long exposures to sunlight do not cause significant damage to it.

Is EPDM rubber breathable?

EPDM rubber is not breathable. It is an elastomer with an airtight character.

Is EPDM rubber waterproof?

Yes, EPDM rubber is waterproof, making the material an ideal choice for applications with moisture exposure.

Is EPDM rubber resistant to UV radiation?

Yes, EPDM rubber is highly resistant to UV radiation.

Is EPDM rubber resistant to oil?

EPDM rubber is not resistant to oil. It can degrade in the presence of this type of substance.

Is EPDM rubber resistant to acids?

EPDM rubber is moderately resistant to some acids. However, it will fail if exposed to strong acids.

Does EPDM rubber shrink over time?

EPDM rubber shrinks only minimally over time, which is one of its advantages.

What is the temperature range of EPDM rubber?

The temperature range of EPDM rubber in its most common form extends from -40 to 110 degrees Celsius. However, in some cases it can be as high as 150 degrees Celsius and, in the case of specialised materials 180 degrees Celsius.

Is EPDM rubber suitable for hot water?

Yes, EPDM rubber is suitable for hot water.

What are the applications of EPDM rubber?

Applications for EPDM rubber cover almost all industries.

Very popular are EPDM gaskets and EPDM washers, which are suitable for static operation in any environment. They are used in doors or windows, among other applications.

Another frequently used product is hydraulic hose made of EPDM rubber (you will read a little more about its advantages later in this article).

EPDM mats are also widely used. They sometimes act as pavements or swimming pool liners, where their weather resistance is very useful. EPDM plates are also used in the food industry.

In addition to this, it is also worth mentioning the products EPDM membrane and EPDM film. Many people seal roofs or terraces with them.

The automotive industry also makes extensive use of this material. EPDM rubber is used to make tyres, inner tubes, bumpers, car door seals and other important parts.

Finally, you will find this material in playgrounds and other recreational and sports spaces, where it acts as a soft and non-slip surface.

What is the application of EPDM hoses?

EPDM hoses, like the material itself, are very versatile in terms of application. Amongst other things, they can be used for the transmission of

- cold and hot water,

- compressed air,

- light chemicals and plant protection products,

- polyurethane, epoxy and solvent-based paints.

As EPDM rubber hoses usually have additional textile reinforcement, they can withstand relatively high operating pressures. In addition, they are characterised by great strength and durability, which translates into many years of trouble-free use.

All this means that EPDM rubber hose offers very good value for money.

What are the trade names of EPDM rubber?

The trade names of EPDM rubber are as follows:

- Nordel,

- Dutral,

- Buna EP,

- Keltan,

- Vistalon,

- Resitrix.

Who invented EPDM rubber?

EPDM rubber was invented by DuPont, which took place in the 1960s.

At that time, several chemical companies such as DuPont, Exxon and Uniroyal were trying to develop a weather-resistant rubber. The hard work eventually paid off, as it bore fruit in the form of ethylene-propylene-diene rubber, commonly known as EPDM.

However, it was DuPont that was the first to perfect the compound, which eventually largely replaced asphalt as the preferred roofing material.

How much does EPDM rubber cost?

How much EPDM rubber costs depends primarily on the supplier and the specifications of the product.

However, when you consider the versatility and durability of the EPDM material, its cost is not prohibitive. All the more so because products of this type do not require any particular maintenance, which adds to the savings in the long term.

Therefore, if you are looking for a product that you would like to use for many years without the risk of failure or damage, the material will meet your expectations.

Take into account, however, that the final cost depends on the technical requirements, size and even thickness of the EPDM, so depending on the product and customer requirements, the price may vary.

What are the disadvantages of EPDM rubber?

The disadvantages of EPDM rubber are: lower resistance to oils and fuels compared to other materials, greater susceptibility to abrasion or possible loss of elasticity at very low temperatures.

Is EPDM rubber safe?

Yes, EPDM rubber is safe. It is considered a biologically and chemically dead material, so it does not threaten the environment.

What damages EPDM rubber?

EPDM rubber is damaged by some oils, fuels and strong acids and alkalis.

Does EPDM rubber crack?

EPDM rubber does not crack if used as intended. It is characterised by its ability to withstand weathering cracks, which can occur under harsh pressure or impact.

Is it possible to walk on EPDM rubber?

You can walk on EPDM rubber but with moderation. Although the rubber is durable, continuous walking can lead to abrasion and faster wear.

Is EPDM rubber better than glass fibre?

Whether EPDM rubber is better than fibreglass depends on the specific application. Both materials have their advantages and disadvantages. EPDM is cheaper and often easier to install, while fibreglass is more resistant and long-lasting.

Which is better: EPDM rubber or PTFE?

EPDM rubber is a better choice for applications requiring flexibility and good weather resistance, such as the automotive and construction industries as it is cheaper. PTFE, on the other hand, will perform much better where excellent chemical resistance and high-temperature performance is needed, such as in the chemical processing and food industries

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

What is EPDM rubber?

What does EPDM stand for?

How is EPDM rubber produced?

What are the properties of EPDM rubber?

Is EPDM rubber durable?

How long will the EPDM rubber last?

How long does EPDM rubber last in the sun?

Is EPDM rubber breathable?

Is EPDM rubber waterproof?

Is EPDM rubber resistant to UV radiation?

Is EPDM rubber resistant to oil?

Is EPDM rubber resistant to acids?

Does EPDM rubber shrink over time?

What is the temperature range of EPDM rubber?

Is EPDM rubber suitable for hot water?

What are the applications of EPDM rubber?

What is the application of EPDM hoses?

What are the trade names of EPDM rubber?

Who invented EPDM rubber?

How much does EPDM rubber cost?

What are the disadvantages of EPDM rubber?

Is EPDM rubber safe?

What damages EPDM rubber?

Does EPDM rubber crack?

Is it possible to walk on EPDM rubber?

Is EPDM rubber better than glass fibre?

Which is better: EPDM rubber or PTFE?

See also other categories