Adiabatic cooling – definition, types, advantages, limitations – A Complete Guide

What is adiabatic cooling?

Adiabatic cooling is a process that involves the reduction of heat by the expansion of a gas or vapour. It occurs when a gas or vapour is allowed to expand without exchanging heat with its surroundings.

This causes them to lose energy and undergo cooling.

Adiabatic cooling works through the relationship between pressure and temperature. When a gas or vapour is compressed without heat exchange, its temperature increases. This is because their molecules forcibly move closer together, which increases the energy.

In contrast, when a gas or vapour is expanded, the opposite process takes place. The molecules expand, doing 'work' on their surroundings, which reduces their energy and temperature.

Take air as an example. As it rises in the atmosphere, it expands because the pressure is lower at higher altitudes. As a result, the air loses energy and cools. Therefore, the temperature usually decreases with increasing altitude.

Know, however, that a perfect adiabatic transformation is not possible in nature. This is because some kind of heat exchange always takes place.

What is the function of adiabatic cooling?

The adiabatic cooling function is primarily about reducing temperature, but it is also useful for increasing humidity.

It is a versatile process that you will use for a variety of applications. It offers relatively high efficiency and produces no emissions. This makes it a good option for eco-friendly cooling solutions.

It can either support the main cooling system or replace it completely.

Where does adiabatic cooling occur?

Adiabatic cooling occurs in a wide variety of locations, both natural and artificial like mountain peaks, engines or cooling towers. We have already mentioned the atmosphere, but this is not the only example. Other sites of adiabatic transformation include:

- Mountain peaks - When the wind forces air to rise and fall near the surface of mountains, it undergoes expansion or compression. As a result, its temperature decreases or increases.

- Engines - When air is compressed in an engine, its temperature rises. This helps to induce ignition

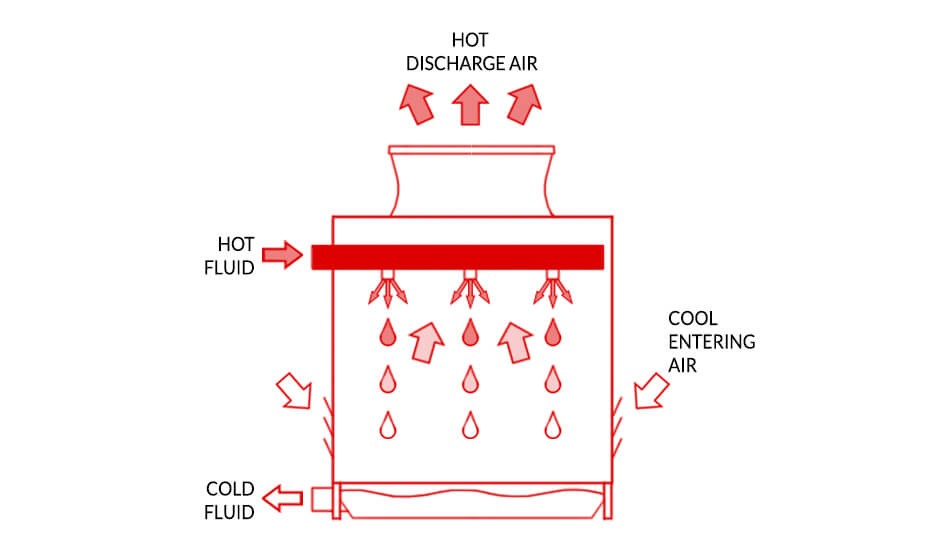

- Cooling towers - They use adiabatic cooling to cool water. First, fans blow warm air onto the water mist. As the water evaporates, it picks up heat from the air, allowing the process to cool.

- Humidifiers - Adiabatic cooling is also used to humidify the air.

What is the difference between adiabatic and evaporative cooling?

The main difference between adiabatic and evaporative cooling is water consumption.

In an adiabatic system, water is only used to cool the air that flows through the coolant hoses. Its consumption is in no way related to the amount of heat to be dissipated, but only to the efficiency of the humidification system in combination with the air mass that flows through it.

Furthermore, in an adiabatic system, water cools the air only on the hottest days of the summer period. For most of the year, cooling works on the dry cooler principle.

Evaporative cooling, on the other hand according to the principles of thermodynamics involves the exchange of heat and mass between water and the flowing air/process. The evaporation of water occurs by taking heat away from the air/process, thus lowering its temperature.

In evaporative systems, water consumption is almost constant all year round. It is closely related to the amount of heat that is dissipated.

It is worth noting that many people use the terms “adiabatic cooling” and “evaporative cooling” interchangeably. This is due to two facts:

- Both systems operate on a similar principle (water cooling of air).

- “Adiabatic” is a somewhat overused term in industrial refrigeration. Because perfect adiabatic exchange (without heat transfer) is not possible.

How does adiabatic cooling work?

Typical adiabatic cooling works as follows

- Draws air from outside.

- Reduces the temperature of the air by evaporating water in its presence.

- Introduces the cooled air to a heat exchanger.

- The heat exchanger eliminates heat energy from the associated process/equipment and transfers it to the cooled air.

- Once heated, the temperature of the circulating air is again reduced by the evaporation process.

- A new cooling cycle begins.

What are the types of adiabatic cooling?

There are three main types of adiabatic cooling - direct adiabatic cooling, indirect adiabatic cooling, two-stage adiabatic cooling.

What is the direct adiabatic cooling?

Direct adiabatic cooling is a process in which there is direct interaction between water and air in the system. The water evaporates directly into the heated air stream to facilitate cooling.

It is the most widely used adiabatic cooling technique in the world.

What is an indirect adiabatic cooling?

Indirect adiabatic cooling is a process in which the water evaporates separately from the air stream to be cooled. Heat exchange takes place at the surface of the tubes through which the hot air flows.

As a result, the temperature decreases without an increase in humidity.

What is the two-stage adiabatic cooling?

Two-stage adiabatic cooling is a process that includes elements of both direct and indirect methods.

The first stage of the process is indirect cooling. The air passes through a heat exchanger, where it releases its temperature to the water without coming into contact with it.

In the second stage, the air flows through the wet pads, similar to a direct system. As a result, it is cooled more deeply and humidified before it enters the desired space.

The combination of the direct and indirect cooling phases allows a greater reduction in temperature than if only one method is used. Therefore, the two-stage system is the most efficient and economical of all those mentioned.

What are the benefits of adiabatic cooling?

The benefits of adiabatic cooling are as follows:

- energy efficiency,

- low installation and running costs,

- simple construction,

- wide range of applications,

- environmental safety.

We explain each of the points below.

Energy efficiency

Adiabatic cooling promotes energy savings. As a rule, only 1 kW of electricity is sufficient to generate 40 kW of cooling power. Moreover, electricity consumption hardly increases on hot days.

The energy efficiency ratio (EER) of this system is approx. 10 times lower than other, more traditional cooling systems.

What about water? Doesn't adiabatic cooling use too much of it?

On the contrary - one cubic metre of water is enough to provide up to 695 kW of cooling power.

Low installation and running costs

Another advantage of adiabatic cooling is the significantly lower cost of installation. Of course, the amount depends on the specifics of the system and its size, but compared to more traditional solutions the cost will be lower.

The same applies to use.

Cooling and ventilation of large buildings is possible with electricity savings. What's more, water consumption levels drop by up to 95% (depending on the specific system and environmental conditions).

Simple construction

The adiabatic cooling system is also simple in its construction when we are talking about a direct system. The whole mechanics are based on passing air through humidified pads.

In indirect and hybrid systems, there are already a bit more complications.

However, adiabatic cooling is nevertheless simpler to build and operate compared to more traditional systems. There is an additional benefit here. Thanks to the simplicity of installation, you will avoid the excessive costs that come with more advanced maintenance.

Wide range of applications

With the development of new adiabatic designs used in liquid cooling and refrigerant condensers, adiabatic cooling systems are finding increasing use in many industries.

Environmental safety

Last but not least, adiabatic cooling is environmentally friendly. The system uses no refrigerants other than water, so it produces no greenhouse gases.

In addition, it requires significantly less electricity and water to operate effectively, thus offering a sustainable way to cool commercial and industrial buildings.

What are the limitations of adiabatic cooling?

Limitations of adiabatic cooling are as follows:

- lower efficiency in humid climates,

- limited cooling capacity,

- larger usable area,

- noise pollution.

Below we explain where the above disadvantages come from.

Lower efficiency in humid climates

As the air in humid climates is already saturated with water vapour to some extent, the effect of adiabatic cooling is worse. This is because the evaporation of water in the system will be limited.

Some tropical countries have such a humid climate that adiabatic cooling cannot provide sufficient cooling capacity. In Europe, however, such a situation almost never occurs.

It only happens shortly before or during heavy rainfall.

In addition, in our climate there are only a few humid days per year on which the adiabatic system cannot cool as effectively. They occur during spring and autumn, when temperatures are still relatively low and humidity is high.

For the rest of the year, adiabatic cooling functions as a highly efficient and sustainable solution.

Limited cooling capacity

The final temperature of the cooled air largely depends on the conditions outside. If it is too hot (e.g. 40 degrees Celsius or more), lowering the temperature to a comfortable 22 degrees Celsius will reduce the temperature - especially for a direct system.

However, hybrid two-stage adiabatic cooling already gives better results. This is because the air returns temperature to the water twice - first indirectly and then directly.

However, this does not change the fact that the system is not suitable if you want very low temperatures.

Larger usable area

Considering replacing a cooling tower with an adiabatic cooling tower? Before you do, consider whether you have enough space in the same location.

Being a less efficient way of cooling, an adiabatic solution will take about 1.5 times more space to achieve the same efficiency. Therefore, it may not be possible to use the same location or pad foundations.

Furthermore, additional building work may be required to accommodate the adiabatic cooler.

Adequate surrounding space is equally important, as it allows air to be drawn through the heat exchange surface. In locations where this may pose a potential problem, it is possible to raise the cooler using a platform. This allows air to be drawn in from underneath.

Another option is a single-sided cooler when the location is against a wall.

Noise pollution

Also consider noise if there are strict levels in your area that cannot be exceeded. An adiabatic cooling tower usually has a higher sound power level at the same load than a cooling tower.

However, there are options to reduce noise levels, such as damping or fan control.

For example: you can choose a larger adiabatic cooling tower, but run the fans at a lower speed. This way you will achieve the required capacity and not exceed the acceptable noise level.

What is the adiabatic cooling used?

Adiabatic cooling is used in data centres, manufacturing, HVAC systems, cooling towers, and agriculture.

Data centres

One of the most important applications for adiabatic cooling is in data centres, which require the right thermal conditions to keep servers running properly.

Traditional cooling systems, such as air conditioning, can sometimes be very expensive to run. Therefore, adiabatic cooling is emerging as a more efficient and cost-effective way to reduce temperatures in data centres.

Manufacturing

Many manufacturing processes generate heat, which can damage equipment and products. Adiabatic cooling lowers the temperature and keeps the plant cool.

HVAC systems

HVAC systems are used to heat and cool homes and businesses. Adiabatic cooling is used as a complement to traditional HVAC systems and chillers or as a stand-alone system to reduce the temperature in a building.

Cooling towers

Cooling towers reduce water temperatures in industrial and commercial applications. Adiabatic cooling can be used to improve their efficiency.

Agriculture

Greenhouses often use adiabatic cooling to regulate temperature and humidity. This helps to protect plants from heat stress and pests.

What is an adiabatic cooling system?

An adiabatic cooling system is a cooling solution that reduces heat by changing the air pressure due to volume expansion.

To achieve this, the system uses an evaporative cooler. Inside it is a large fan that draws in warm air from outside through water-wetted pads. As the water evaporates, the air cools and enters the desired space.

The temperature can be controlled by adjusting the airflow in the cooler.

How is an adiabatic cooling system constructed?

An adiabatic cooling system is constructed of an enclosed metal structure inside of which an electric fan circulates air through moistened panels (usually cellulose) or a water mist.

It then blows the cooled air where it is needed.

At the bottom of the adiabatic cooler is a water reservoir, which is transported by a pump towards the spray nozzles. The latter maintain the humidity of the cellulose panels or generate a water mist.

In addition, the frequency converter is responsible for controlling the speed of the fan to regulate the air flow. This is very important because the air should not flow through the panels too quickly. Otherwise, it will absorb too little water.

How to maintain an adiabatic cooling system?

To look after your adiabatic cooling system, focus primarily on the following points:

- Regularly check the water level in the tank to ensure that the system has enough water to run.

- Regularly clean the water tank and spray nozzles to prevent clogging and ensure efficient operation of the system.

- Check the cellulose panels regularly for signs of wear. Replace them if necessary.

- Regularly check the fan vanes and motor for damage or wear. Replace them if necessary.

- Check air filters regularly. Replace them when they become dirty or clogged.

- Check the heat exchanger regularly for any signs of damage or corrosion. Replace it if necessary.

- Monitor temperature and humidity levels in the cooled space to ensure the system is operating efficiently

- Regularly check the system for leaks and repair them quickly. This will prevent water damage and ensure your system is running efficiently.

- Schedule regular maintenance visits with a qualified technician to ensure your cooling is running at maximum efficiency. The specialist will identify any potential problems before they become serious.

In general, looking after an adiabatic cooling system involves regular maintenance and inspection. This will ensure that the installation is operating efficiently. So follow the above tips if you want to increase the life and efficiency of your cooling system.

What is the future for adiabatic cooling?

The future of adiabatic cooling looks very promising given the strong market growth in the industrial sector and the popularity of green technology.

Here are some potential future directions for adiabatic cooling:

- Increased adoption of adiabatic technology across industries due to its effectiveness in hot, dry conditions while using less water.

- Continuing to improve efficiency, cost-effectiveness and reduce environmental impact.

- Integrate adiabatic cooling systems with other green technologies (e.g. solar energy) to create more sustainable and efficient cooling systems.

- Intensify research in adiabatic cooling systems in search of new applications and potential uses for the technology.

In general, the future of adiabatic cooling looks very bright. Continued market growth and development, increased adoption of the technology and advances in its sophistication are all doing their part.

Adiabatic cooling systems are already establishing themselves as an effective, energy-efficient and cost-effective solution for many industries.

FAQ

Why is adiabatic cooling important?

Adiabatic cooling is important because it is a natural process that serves to reduce the temperature of air and other gases. As a result, it is a valuable tool in various applications such as air conditioning, cooling towers and greenhouses.

What is the difference between adiabatic heating and adiabatic cooling?

The main difference between adiabatic heating and adiabatic cooling is the direction fo the temperature change. Adiabatic heating is the process of increasing the temperature of a gas by compressing it. Adiabatic cooling is the process of lowering the temperature of a gas by expanding it. In both cases, heat is neither added to nor removed from the gas. The only way to change the temperature is through the “work” that the gas has done.

Does adiabatic cooling cause the air to rise?

No, adiabatic cooling does not cause the air to rise. On the contrary, the cooler the air is, the denser it becomes, making it sink.

Is air conditioning adiabatic cooling?

No, standard air conditioning is not adiabatic cooling. Air conditioning works by using a compressor. This is a different process to adiabatic cooling because heat is added to the air in order to cool it later.

Why does the temperature drop with adiabatic cooling?

The temperature drops with adiabatic cooling because when a gas expands, it does "work" on the surrounding environment. "Work" consumes the internal energy of the gas, which leads to a drop in temperature.

Articles author

Bartosz Kułakowski

CEO of Hosetech Sp. z o.o.

Bartosz Kulakowski is an industrial hoses and couplings specialist with over 10 years of experience. Bartosz has been present in the technical industry since 2013. He gained experience as a technical and commercial advisor in the sector of plastic conveyor belts, steel structures, industrial hoses, and connectors. Since 2016, he has specialized exclusively in hoses and connectors. In 2019 he opened his own business under the HOSETECH Bartosz Kulakowski brand and since July 2022 he has been the CEO of the capital company HOSETECH Sp z o. o. (LLC).

Table of Contents

What is adiabatic cooling?

What is the function of adiabatic cooling?

Where does adiabatic cooling occur?

What is the difference between adiabatic and evaporative cooling?

How does adiabatic cooling work?

What are the types of adiabatic cooling?

What is the direct adiabatic cooling?

What is an indirect adiabatic cooling?

What is the two-stage adiabatic cooling?

What are the benefits of adiabatic cooling?

Energy efficiency

Low installation and running costs

Simple construction

Wide range of applications

Environmental safety

What are the limitations of adiabatic cooling?

Lower efficiency in humid climates

Limited cooling capacity

Larger usable area

Noise pollution

What is the adiabatic cooling used?

Data centres

Manufacturing

HVAC systems

Cooling towers

Agriculture

What is an adiabatic cooling system?

How is an adiabatic cooling system constructed?

How to maintain an adiabatic cooling system?

What is the future for adiabatic cooling?

FAQ

Why is adiabatic cooling important?

What is the difference between adiabatic heating and adiabatic cooling?

Does adiabatic cooling cause the air to rise?

Is air conditioning adiabatic cooling?

Why does the temperature drop with adiabatic cooling?

See also other categories